AI Series Circulating Air Refrigeration Unit

APLICAÇÕES

Applied to high and low temperature testing of semiconductor equipment. Electronic equipment high and low temperature constant temperature test cold and heat source; independent refrigeration cycle fan unit; can work continuously for a long time, automatic defrosting, and the defrosting process does not affect the storage temperature.

Caraterísticas do produto

Parâmetros do produto

AI -105℃~+125℃

| Modelo | AI-6535 AI-6535W |

AI-8035W | AI-1055W | |

| Faixa de temperatura | -65℃~+125℃ | -80℃~+125℃ | -105℃~+125℃ | |

| Modo de controlo | Controlador PID adaptativo | |||

| Protocolo de comunicação | Protocolo MODBUS RTU, Interface RS 485 | |||

| Reação à temperatura | PT100 | |||

| Painel de controlo | 7-inch touch screen, show temp. curve/ EXCEL date output | |||

| Precisão da temperatura | ±0,05℃(Temperatura de saída em estado estacionário) | |||

| Potência de aquecimento | 3,5KW | 3,5 kW | 3,5 kW | |

| refrigeração capacidade |

125℃ | 3,5KW | 3,5 kW | 3,5 kW |

| 50℃ | 3,5 kW | 3,5 kW | 3,5 kW | |

| 20℃ | 3,5 kW | 3.5kw | 3.5kw | |

| 0℃ | 3,5 kW | 3.5kw | 3.5kw | |

| -20℃ | 3kW | 3,5 kW | 3,5 kW | |

| -40℃ | 2,1KW | 2.5kW | 3,5 kW | |

| -60℃ | 1KW | 2,1kw | 3kw | |

| -75℃ | 1kw | 2kw | ||

| -95 | 1KW | |||

| Fluxo de ar circulante | 550m³/h | |||

| Interface de ar de entrada e saída | DN125 | |||

| Compressor | Emerson Copeland scroll flexible compressor | |||

| Proteção de segurança | Self-diagnosis function; Phase sequence protection. freezer overload protection; high pressure switch. overload relay. thermal protection device. |

|||

| Defrosting device | There are installed defrosting device and condensate drain inside | |||

| Continuous running | Running continuously | |||

| Timing operation | Can set timed start and stop time | |||

| refrigerante | R404A R23 | R404A R508B | R404A R23 R14 | |

| Arrefecimento por água | 1200L/H 1.5bar~4bar | 1600L/H 1.5bar~4bar | 2600L/H 1.5bar~4bar | |

| Dimensão(cm) | 55*100*175 | 55*100*175 | 70*100*175 | |

| Peso | 280kg | 300 kg | 360 kg | |

| Material da casca | Cold rolled sheet spray coating REL 7035 | |||

1. Widely used in high and low temperature testing of semiconductor equipment.Cold and heat source of electronic equipment at high temperature and low temperature;

2. Independent refrigeration circulating air units;

3. Can work continuously for a long time, automatic defrosting, defrosting process does not affect the storage temperature;

4. Modular design, easy replacement of spare machine (if there are 10 machines, as long as a standby unit can);

5. Solve frequent open and close doors, evaporating system frosting problems;Evaporation system defrosting process does not affect.

6. Construct a set of high and low temperature and constant greenhouse (according to the drawings provided, the box can be joined together like building blocks to connect the electricity and water and set the temperature to work)

Vantagens do produto

- Resultados eficientes em termos de estabilidade e repetibilidade da produção;

- Utilização de permutadores de calor de placas e aquecedores de condutas para melhorar as taxas de arrefecimento e aquecimento;

- Gama de temperaturas muito ampla, sem necessidade de substituir o meio líquido;

- Sistema totalmente fechado, que prolonga a vida útil dos líquidos condutores de calor;

- Adotando a bomba de acionamento magnético, não há problema de vazamento de vedação do eixo;

- Tecnologia de arrefecimento de alta temperatura, iniciar diretamente o compressor para arrefecer a 300 ℃.

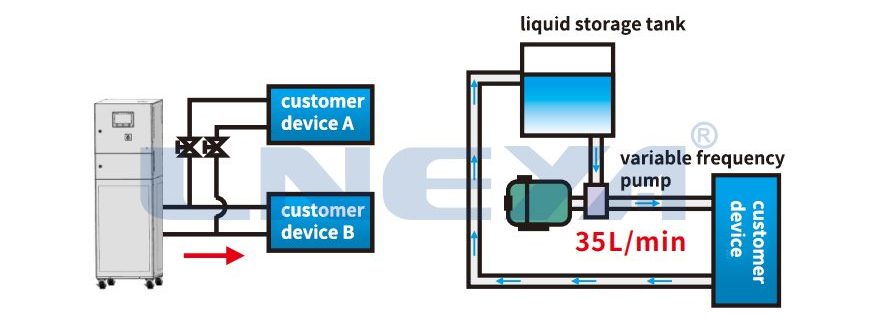

A bomba de frequência variável pode ajustar a pressão hidráulica de circulação e o caudal

sinal de saída do cliente

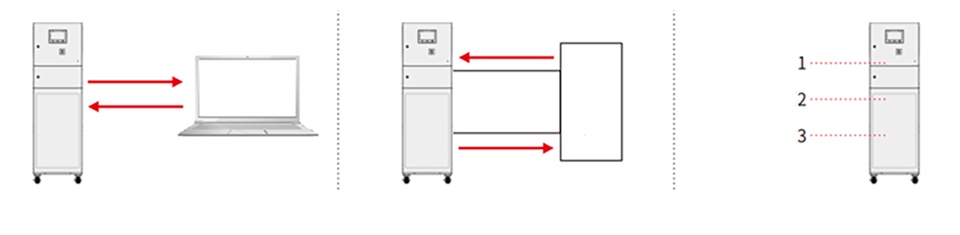

Função de comunicação

APLICAÇÕES

Por exemplo, refrigeradores que controlam a temperatura de processamento nos equipamentos Fab.

Arrefecimento de sensores CMOS/CCD em sistemas de metrologia de semicondutores.

Refrigerador de recirculação para sistema AOI de medição de semicondutores.

Refrigerador de canal único arrefecido a ar, concebido principalmente para máquinas de gravação. É utilizado para fornecer um controlo de temperatura independente para as paredes laterais da câmara.

Utilizado para Gravação e deposição por plasma em bisel; Gravação térmica em camada atómica de tungsténio metálico.

LNEYA fornece serviços personalizados de Chiller

tamanhos de refrigeradores personalizados

Quer se trate de refrigeradores portáteis, compactos, grandes ou pequenos, podemos concebê-los à medida das suas necessidades. Independentemente do número de toneladas de refrigerador de que necessita, podemos criar a melhor solução.

tipos de chillers personalizados

Fornecemos chillers de vários tipos de refrigeração, incluindo, entre outros, chillers arrefecidos a ar, arrefecidos a água e de condensação evaporativa. Independentemente do tipo de compressor de refrigeração, podemos projectá-lo de acordo com os seus requisitos.

gamas de temperatura personalizadas

Podemos criar uma solução personalizada para temperaturas de -150 ℃ a +350 ℃. Faixas de temperatura personalizadas para indústrias específicas.

tensão do chiller personalizada

Personalize a tensão e a fase do chiller de acordo com as suas necessidades. Opcional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

Visitar a fábrica da LNEYA

Porquê escolher a lneya como seu fornecedor de controlo de temperatura?

Anos de experiência

Clientes satisfeitos

m² Área de produção

Tecnologias patenteadas

contactar-nos

Envie-nos sua solicitação e entraremos em contato com você em até 24 horas

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor