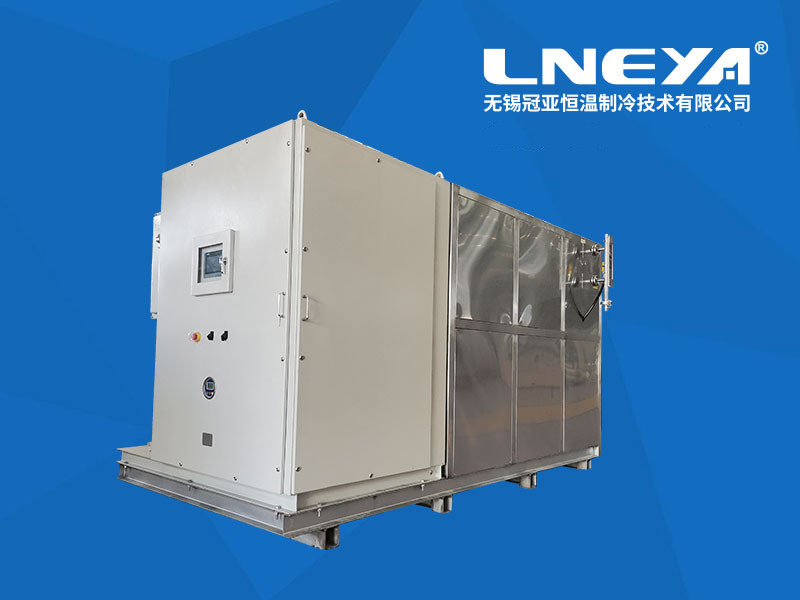

Inspeção de manutenção da unidade de refrigeração de baixa temperatura

Low-temperature refrigeration units usually need to do a maintenance. After the maintenance is done, it is not easy to fail, and there will be more markets. If it is not easy to fail, it will not stop working, which is equivalent to saving the company’s cost. It should be noted that the low-temperature refrigeration unit is maintained. It is very important to lubricate the industrial machinery at ordinary times, because it is always in operation, and the parts that run frequently must be lubricated regularly. If lubrication is not added, the friction will be large. The parts are worn out, so they should be observed and inspected regularly.

Different configurations use different lubricants:

If a problem with the low-temperature refrigeration unit is found, it should be replaced immediately. Different configurations require different lubricating oil. Remember to use special lubricating oil, don’t use a kind of lubricating oil casually. If you use the wrong lubricating oil, the effect of lubricating oil will not be good. It is also possible that the lubricating oil will fall directly from the top when the lubricating oil is just applied. What a role.

Regularly replace the filter drier:

The filter drier should also be replaced. The filter drier is a very important component to ensure the normal circulation of the refrigerant. Water and refrigerant are incompatible with each other. If the system contains water, this will greatly affect the low-temperature freezing The operating efficiency of the unit, so it is very important to keep the system dry. If you want the internal dry, you need to replace the filter element inside the filter regularly.

Regularly check the pipeline for scale:

One of the usual maintenance of low-temperature refrigeration units should also pay attention to check whether the pipeline has deposited scale? If there is too much scale, it will significantly affect the heat transfer. The contact surface of cooling water will also shrink, the quantity will decrease, and the condensing pressure will increase. Usually, it is necessary to use tap water to use a water-cooled chiller. The quality of tap water in different regions of our country is different. Some are alkaline and some are alkaline. If the sex is small, some have more impurities, some have less impurities, and if there are more impurities for a long time, some very obvious scales will easily appear, and the effects we have just mentioned will appear.

To Sum Up

We need to carry out regular maintenance and inspection of the equipment, which can not only improve the efficiency of the machine but also save costs.

Recomendações relacionadas

-

-

A que devo prestar atenção ao adicionar refrigerante a um chiller arrefecido a água?

1754Na nossa vida, acreditamos que toda a gente está muito familiarizada com a refrigeração. No ar condicionado central e na indústria de arrefecimento de processos de produção industrial, os pequenos chillers arrefecidos a água são mais comuns. Esta unidade é composta por um compressor no interior...

Ver detalhes -

Novo método de ensaio energético e caso de aplicação do termóstato de simulação de temperatura

1473LNEYA bateria de veículo de energia nova teste de ciclo de alta e baixa temperatura é um dos equipamentos mais utilizados em testes de bateria de veículos modernos. A bateria de lítio é uma das baterias mais comuns. A que é que se deve prestar atenção quando a utilizamos? ...

Ver detalhes -

Descrição do desempenho em caso de avaria da câmara de ensaio de choque térmico

1552The temperature shock test chamber is widely used in various major industries. When users purchase, they hope that their temperature impact test chamber can be used for a long time. Therefore, it is necessary to understand each fault of the temper...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor