A que devo prestar atenção ao adicionar refrigerante a um chiller arrefecido a água?

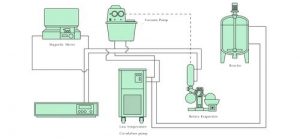

In our life, we believe that everyone is

very familiar with refrigeration. In the central air conditioning and

industrial production process cooling industry, small water-cooled chillers is

more common. This unit is composed of a compressor in the fuselage, a

horizontal shell and tube condenser, an evaporator, a thermal expansion valve,

and some related parts. Under the cooperation of these auxiliary parts, the

overall small water cooled chiller is compact in structure, convenient in

operation and control, and is popular among the public in the market.

For refrigeration systems that do not have

a high pressure reservoir and a low pressure vapor-liquid separator, the

control of refrigerant charge is particularly important. Because the

refrigeration system is a condenser and also acts as a high-pressure reservoir,

the refrigerant is stored in the condenser, and the condenser is cooled. The

heat dissipation area is reduced and the condensing pressure is increased,

resulting in a decrease in cooling capacity.

For the control of the refrigerant charge

of such small water-cooled chillers, the following methods are followed during

the filling process:

First, touch the temperature of the

condenser casing.

The upper outlet of the condenser outlet is

heated above the outlet, and the outlet below the outlet is cool. (There is a

description of the high temperature exhaust of the compressor in the inside.

The cooling indicates that the small water-cooled chillers is a liquid space.)

Second, look at the inspiratory pressure.

Corresponding to the temperature of the

refrigerant water in the evaporator. (That is, corresponding to the evaporation

temperature.)

Third, look at the compressor return pipe

temperature.

The high-temperature unit return pipe

should be cooled and dew, but it can be dew condensation to the compressor

return valve; the low-temperature unit return pipe should be frosted, but the

frost can be connected to the compressor return valve. If condensation or frost

builds up on the compressor casing, liquid refrigerant will enter the

crankcase, causing the compressor to run back and cause liquid

problem.

The above is a partial analysis of our

LNEYA technicians for water-cooled chillers. Regarding the specific use of our

water-cooled chillers, you can contact us sales@lneya.com for more detailed

instructions.

Recomendações relacionadas

-

Manutenção do Condensador em Chillers de Baixa Temperatura

1399Nos últimos anos, com a melhoria do nível de produção industrial da China, muitas máquinas e equipamentos industriais profissionais fornecem maior ajuda para diferentes produções industriais. Como um equipamento de refrigeração industrial muito prático, a l...

Ver detalhes -

Low-temperature coolant circulation pump used with rotary evaporator

1932The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Ver detalhes -

Equipamento de teste de bateria de carro de energia nova para descrição da bateria

1511As matérias-primas da bateria de chumbo-ácido são fáceis de obter, o preço é relativamente baixo, o desempenho de descarga de alta taxa é bom, o desempenho de temperatura é bom, pode trabalhar no ambiente de -40 ~ + 60 ° C, adequado para carregamento flutuante, longo serviço ...

Ver detalhes -

Instruções para o congelador 100p de LNEYA

1880Quando o utilizador comprar e utilizar o congelador 100p, a LNEYA terá instruções de utilização relevantes que serão enviadas ao utilizador juntamente com o aparelho. Então, a que é que devo prestar atenção quando utilizar o congelador 100p? Ao receber o equipamento, o utilizador deve...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor