Cooling and shrinking assembly freezer for metal parts and common assembly methods in the industry

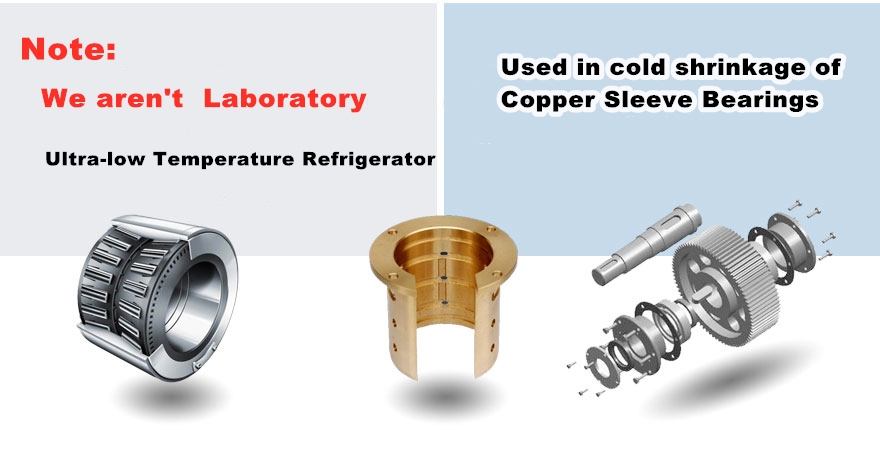

In the cold shrink production of copper sleeves, bearings, etc., quick-freezing cryogenic boxes are widely used in mechanical assembly.

Copper sleeve cooling shrink assembly cabinet variable temperature assembly method is to heat the hole or cool the shaft. When the diameter is larger or the interference amount is larger, the parts will be damaged if assembled at normal temperature. In this case, the method of heating and containing the parts or cooling the contained parts should be used for assembly, so that the interference amount can be reduced in a short time or Form a gap to facilitate assembly of parts. When the part returns to normal temperature, the designed interference amount is generated, and its tightening degree is higher than that of the press-in at normal temperature. In practice, heating is often used to assemble parts. Heating methods include water, oil, electricity, oxyacetylene, and steam.

Normal temperature assembly method The normal temperature assembly method uses external force to assemble the contained parts into the contained parts at normal temperature. According to the size of the interference amount, a hand-hammering method or a press-in method is used in a timely manner.

Regardless of which assembly method is used, the following processes must be performed on the assembly parts.

Before assembly, the surface of the parts that cooperate with each other should be checked for burrs, dents, pits and other defects. If the above defects are found, they should be handled properly. These defects may be left over during processing, or they may be caused by collisions during transport.

So, what are the common assembly methods?

(1) Press-fitting by press This method is easy to operate and has high efficiency, but the installation position of the press must be fixed, it is suitable for use on the assembly line, the structural parts can automatically enter the installation position and be aligned, and each press There is a very specific division of labor. Our company has many product models and many types of shaft sleeves. Many structural parts adopt the as-built method, and the press-fit method is not applicable.

(2) Hammering and pressing method This method is flexible and adaptable. The use of a stamper during hammering can ensure the size, but this method is labor-intensive, the assembly guidance is not controlled, and the shaft sleeve will be scrapped when it is skewed.

(3) The fit between the sleeve and the hole of the hot-loading method is a transitional fit, and different media are used for heating according to the temperature difference requirements, but it is difficult to adopt for large-scale structural parts of construction machinery.

(4) Copper sleeve cooling shrink assembly cabinet cold installation method This method freezes the sleeve, and can be easily inserted into the structural component hole after shrinking, and the required fit can be obtained after the temperature is restored at room temperature. This method is easy to implement, and the copper jacket cooling shrink assembly cabinet is the method of choice.

Recomendações relacionadas

-

Unidade de controlo da temperatura do processo de produção de semicondutores e do processo de ensaio

1473Refrigerador de processo de ensaio de semicondutores LNEYA

Ver detalhes -

Energy Conservation is Crucial for Developing Ultra Low Temperature Recirculating Chillers

3147With the continuous development of chemical, refrigeration and pharmaceutical industries, environmental pollution is put on the agenda earlier. As an editor of which is the industrial chiller, I can say that except for corresponding to the environ...

Ver detalhes -

How to solve the common faults of industrial circulating chillers?

1696For industrial circulating chillers, if they are always in a high-temperature operating state, a large amount of cold air will be seriously lost. After ensuring the sealing effect of the use environment, effective thermal insulation can be carried...

Ver detalhes -

Common Faults of Salt Spray Environmental Chambers

1583The enterprise users are often at a loss when dealing with common faults in the salt spray environmental chamber. For this reason, Wuxi LNEYA, a manufacturer of the salt spray environmental chamber, specially reorganized the related common fault t...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor