Talk about the main points of choice for circulating water chiller in laboratory

Circulating water cooler is also called chiller. It is a kind of cooling water equipment that can provide constant temperature, constant flow and constant pressure. Currently there are many kinds of chillers in the market. How to buy a suitable chiller for the laboratory?

Circulating water coolers are divided into two types, air-cooled and water-cooled, according to the condensation method, and water-cooled usually requires a matching cooling tower or water tank, and special water inlet and drainage are required, which requires relatively high laboratory hardware facilities, so we only Discuss the laboratory circulating water cooler here.

Generally, you can choose from the following aspects:

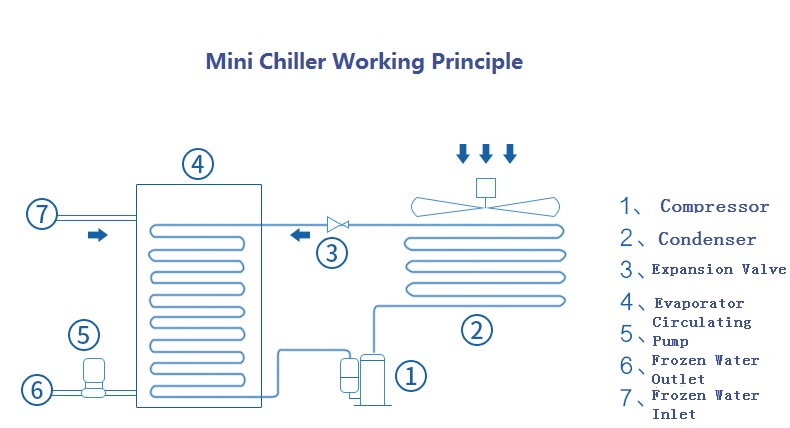

1. Compressor: The cost of the compressor alone accounts for a large part of the cost of the chiller, and also determines the cooling capacity, so it is the core component. You can usually choose from four aspects: brand, stability, energy consumption and service life. 2. Components: relays, thermal protectors, expansion valves, pressure controllers, etc. The quality of small components determines the reliability of the chiller.

Lneya’s FL-800N is a circulating water cooler specially developed for the laboratory, temperature range: -15°C~30°C, ASET multi-function controller, water tank temperature control, customizable temperature control accuracy ±0.5℃ . When the temperature is 20℃, the cooling capacity is 0.9 kilowatts; when the temperature is 10℃, the cooling capacity is 0.76 kilowatts; when the temperature is -10℃, the cooling capacity is 0.35 kilowatts. The refrigerant is R404A (optional R448), and the external dimensions are 415*225*497 (mm).

The fully enclosed circulation system can effectively prevent the evaporation and pollution of the heat transfer medium and save resources. It is widely used in low-temperature conditions that require chemical, biological, and physical experiments at low temperatures. It can be combined with rotary evaporator, glass reactor and other instruments to carry out various chemical reactions. The FL-800N circulating water cooler will go through 24 hours of uninterrupted testing in the workshop before it is sent to the customer to ensure that the customer does not have hidden dangers before using the equipment.

Recomendações relacionadas

-

Application and advantages of new energy automotive motor test equipment

992LNEYA's new energy motor test equipment is used in HEV (Hybrid Electric Vehicle), BEV (Electric Vehicle), Hydrogen Power Vehicle, Fuel Cell Electric Vehicle, EREV (Extended Range Electric Vehicle) and other new energy vehicles. LNEYA's equipment a...

Ver pormenores -

Closed circulation cooling system debugging attention note

1072Closed circulation cooling system needs to pay attention to some common problems during commissioning. Do a good job in debugging work. LNEYA manufacturers remind users that only when they are ready to work can they be better debugged. The prepara...

Ver pormenores -

The safety of heat transfer oil in water-cooled chillers

1003In order to achieve better operating efficiency, water-cooled chillers need to choose branded heat transfer oil, but you need to pay attention to safe placement, a little carelessness will cause adverse effects. Although the heat transfer oil of t...

Ver pormenores -

What should I pay attention to when replacing a water-cooled chiller compressor

998Once the compressor of the water-cooledchiller fails, the compressor needs to be replaced in time, but the replacementof the compressor is not as simple as imagined.Before the water-cooled chiller compressoris replaced, the reasons for the dama...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor