Normal & Low Temperature Chillers -40℃~160℃

Control Temperature & Flow Systems

For Vehicle Components Testing,Hydrogen energy industry

Control temperature & flow system supports one to many, meaning that one refrigeration and heating temperature control flow host can control 2-6 different test benches or demand temperature control flow devices. Support two one to many modes, one is that temperature/flow/pressure can be independently controlled (T-series), and the other is that temperature is consistent across multiple groups, and flow/pressure is independently controlled (S-series).(LNEYA’s chiller supports both indoor and outdoor options.)

The automotive industry must ensure that its products operate over this wide temperature range and do not fail or material fatigue under rapid temperature changes.

Therefore, material and component testing, including temperature simulation, is very important and indispensable for the automotive industry, including all suppliers.

On the test benches in the automotive industry, highly dynamic temperature control systems are used for material and component testing, which can achieve precise regulation and rapid temperature changes. Only precise temperature management can provide reliable and repeatable results. The temperature control system provides a constant temperature or a complex temperature curve to the test bench directly or indirectly through a liquid medium. In addition to the temperature of the medium, temperature control systems also allow precise control of flow rates and operating pressures. Temperature control systems are used primarily in two ways: They simulate external ambient conditions in climate chambers or replace internal systems, such as the cooling circuit of an engine. The latter allows realistic conditions to be created on test benches, where test specimens are supplied with coolant according to operational requirements, such as in a vehicle.

Fornecemos aos nossos clientes da indústria automóvel dispositivos de elevado desempenho. Estes não só cobrem dinamicamente toda a gama de temperaturas de -40°C a +160°C e as rápidas mudanças de temperatura necessárias nos bancos de ensaio.

KRY series advantages

● Efficient production stability and repeatability results;

Utilização de permutadores de calor de placas e aquecedores de condutas para melhorar as taxas de arrefecimento e aquecimento;

● Very wide temperature range, no need to replace liquid medium;

Sistema totalmente fechado, que prolonga a vida útil dos líquidos condutores de calor;

● Adopting magnetic drive pump, there is no problem of shaft seal leakage

LOW TEMPERATURE SERIES

KRY -20℃~+100℃

| Modelo |

KRY-255

KRY-255W |

KRY-275

KRY-275W |

KRY-2A10

KRY-2A10W |

KRY-2A15

KRY-2A15W |

KRY-2A25

KRY-2A25W |

KRY-2A38W |

| Gama de temperaturas |

-20℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Saída do caudal |

1~15 L/min |

1~25 L/min |

1~30 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

| Precisão do caudal |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Capacidade de aquecimento |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| Capacidade de resfriamento |

100℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| 20℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| 0℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| -15℃ |

2,8kW |

3,8kW |

4,6kW |

7kW |

12kW |

16kW |

| Tamanho da conexão |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

| Water-cooled type W at 25℃ |

1900L/H

ZG3/4 |

2500L/H

ZG3/4 |

3000L/H

ZG1 |

4000L/H

ZG1 |

6000L/H

DN32 |

9000L/H

DN40 |

| Potência 380V50HZ |

11kW |

14kW |

19kW |

23kW |

31kW |

45kW |

| Dimensão(cm) |

55*100*175 |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

| Peso |

230 kg |

250 kg |

300 kg |

320 kg |

570 kg |

830 kg |

| Opcional |

Extend to -40~+135℃ |

KRY -40℃~+100℃

| Modelo |

KRY-455

KRY-455W |

KRY-475

KRY-475W |

KRY-4A10

KRY-4A10W |

KRY-4A15

KRY-4A15W |

KRY-4A25

KRY-4A25W |

KRY-4A38W |

KRY-4A60W |

| Gama de temperaturas |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Saída do caudal |

1~25 L/min |

1~25 L/min |

1~25 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

| Precisão do caudal |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Capacidade de aquecimento |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| Capacidade de resfriamento |

100℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 20℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 0℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| -20℃ |

2,8kW |

4,5 kW |

6kW |

10kW |

16kW |

25kW |

35kW |

| -35℃ |

1,2kW |

1,8kW |

2.5kW |

4kW |

6,5 kW |

10kW |

15kW |

| Tamanho da conexão |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

| Water-cooled type Wat25度 |

1900L/H

ZG3/4 |

2500L/H

ZG3/4 |

3000L/H

ZG1 |

4000L/H

ZG1 |

6000L/H

DN32 |

9000L/H

DN40 |

15000L/H

DN50 |

| Potência 380V50HZ |

10kW |

14kW |

17kW |

25kW |

38kW |

58kW |

84kW |

| Dimensão(cm) |

55*100*175 |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

200*145*205 |

| Peso |

250 kg |

280kg |

320 kg |

360 kg |

620kg |

890kg |

1300KG |

| Opcional |

Extend to -40~+135℃ |

KRY -40℃~+100℃ 2T

| Modelo |

KRY-475/2T

KRY-475W/2T |

KRY-4A15W/2T |

KRY-4A25W/2T |

KRY-4A38W/2T |

KRY-4A60W/2T |

| Gama de temperaturas |

-40℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Precisão do controlo do caudal/Grupo |

1~25 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

| Precisão da vazão/grupo |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Número de grupos de saída de fluido |

2 grupos |

2 grupos |

2 grupos |

2 grupos |

2 grupos |

| Controle de pressão/grupo |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Capacidade de aquecimento |

7.5kW*2 |

10kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

| Capacidade de resfriamento |

100℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 20℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 0℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| -20℃ |

4.5kW*2 |

8.5kW*2 |

14kW*2 |

22kW*2 |

35kW*2 |

| -35℃ |

1.8kW*2 |

4kW*2 |

6.5kW*2 |

10kW*2 |

15kW*2 |

| Water-cooled type Wat 20度 |

4000L/H

ZG1 |

8000L/H

DN32 |

12000L/H

DN40 |

20000L/H

DN50 |

30000L/H

DN65 |

| Dimensão(cm) |

28kW |

45kW |

70kW |

108kW |

158kW |

| Resfriado a água cm |

80*100*185 |

100*150*185 |

200*145*205 |

200*145*205 |

250*145*225 |

| Peso |

660KG |

850KG |

1350KG |

1800KG |

2600KG |

| Opcional |

Extend to -40~+135℃ |

KRY -20℃~+100℃ 6S

| Modelo |

KRY-2A25W/6S |

KRY-2A38W/6S |

KRY-2A60W/6S |

| Gama de temperaturas |

-20℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

| Precisão do controlo do caudal/Grupo |

1~25 L/min |

1~25 L/min |

1~40 L/min |

| Precisão da vazão/grupo |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Número de grupos de saída de fluido |

6 grupos |

6 grupos |

6 grupos |

| Controle de pressão/grupo |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Capacidade de aquecimento |

15kW |

25kW |

38kW |

| Capacidade de resfriamento |

100℃ |

25kW |

38kW |

60kW |

| 20℃ |

25kW |

38kW |

60kW |

| 0℃ |

25kW |

38kW |

60kW |

| -15℃ |

10kW |

15kW |

24kW |

| Water-cooled type Wat 20度 |

8000L/H

DN40 |

12000L/H

DN50 |

20000L/H

DN65 |

| Potência 380V50HZ |

36kW |

51kW |

75kW |

| Resfriado a água cm |

200*145*205 |

200*145*205 |

200*145*205 |

| Peso |

900 kg |

1100 kg |

1750kg |

KRY -40℃~+100℃ 6S

| Modelo |

KRY-4A25W/6S |

KRY-4A38W/6S |

KRY-4A60W/6S |

| Gama de temperaturas |

-40℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

| Precisão do controlo do caudal/Grupo |

1~25 L/min |

1~25 L/min |

1~40 L/min |

| Precisão da vazão/grupo |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Número de grupos de saída de fluido |

6 grupos |

6 grupos |

6 grupos |

| Controle de pressão/grupo |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Capacidade de aquecimento |

15kW |

25kW |

38kW |

| Capacidade de resfriamento |

100℃ |

25kW |

38kW |

60kW |

| 20℃ |

25kW |

38kW |

60kW |

| 0℃ |

25kW |

38kW |

60kW |

| -20℃ |

14kW |

22kW |

35kW |

| -35℃ |

5kW |

8kW |

13kW |

| Water-cooled type Wat 20度 |

8000L/H

DN40 |

12000L/H

DN50 |

18000L/H

DN65 |

| Potência 380V50HZ |

38kW |

55kW |

82kW |

| Dimensão(cm) |

200*145*205 |

200*145*205 |

200*145*205 |

| Peso |

900 kg |

1200kg |

1950kg |

| Opcional |

Extend to -40~+135℃ |

NORMAL TEMPERATURE SERIES

KRY 0℃~+100℃

| Modelo |

KRY-25 |

KRY-55 |

KRY-75 |

KRY-A10 |

KRY-A15

KRY-A15W |

KRY-A25

KRY-A25W |

KRY-A38W |

KRY-A60W |

| Gama de temperaturas |

0℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Saída do caudal |

2~20 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

5~50 L/min |

5~50 L/min |

| Precisão do caudal |

±0.2 L/min |

| Capacidade de aquecimento |

2.5kW |

5,5 kW |

7,5 kW |

10kW |

15kW |

15kW |

25kW |

38kW |

| Capacidade de resfriamento |

100℃ |

2.5kW |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 20℃ |

2.5kW |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 5℃ |

1,8kW |

3,8kW |

5,2kW |

7kW |

11kW |

18kW |

27kW |

42kW |

| Tamanho da conexão |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

| Water-cooled type Wat25度 |

|

|

|

|

3200L/H

ZG1 |

6000L/H

G1 1/4 |

9000L/H

DN40 |

15000L/H

DN50 |

| Potência 380V50HZ |

4.5kW220V |

8,5 kW |

11,5 kW |

16kW |

18kW |

28kW |

40kW |

61kW |

| Dimensão(cm) |

50*85*145 |

55*100*175 |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

100*150*185 |

| Peso |

220kg |

250 kg |

280kg |

320 kg |

360 kg |

620kg |

890kg |

1300KG |

KRY 0℃~+100℃ 2T

| Modelo |

KRY-25/2T |

KRY-55/2T |

KRY-75/2T |

KRY-A10/2T |

KRY-A15W//2T |

KRY-A25W/2T |

KRY-A38W/2T |

KRY-A60W/2T |

| Gama de temperaturas |

0℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Saída do caudal |

2~20 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

5~50 L/min |

5~50 L/min |

| Precisão do caudal |

±0.2 L/min |

| Capacidade de aquecimento |

2.5kW*2 |

5.5kW*2 |

7.5kW*2 |

10kW*2 |

15kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

| Capacidade de resfriamento |

100℃ |

2.5kW*2 |

5.5kW*2 |

7.5kW*2 |

10kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 20℃ |

2.5kW*2 |

5.5kW*2 |

7.5kW*2 |

10kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 5℃ |

1.8kW*2 |

3.8kW*2 |

5.2kW*2 |

7kW*2 |

11kW*2 |

18kW*2 |

27kW*2 |

42kW*2 |

| Tamanho da conexão |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

| Water-cooled type Wat25度 |

|

|

|

|

5600L/H

DN32 |

10000L/H

DN40 |

17000L/H

DN50 |

24000L/H

DN65 |

| Potência 380V50HZ |

9kW |

19kW |

23kW |

29kW |

34kW |

52kW |

80kW |

120kW |

| Dimensão(cm) |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

200*145*205 |

200*145*205 |

250*145*225 |

| Peso |

260KG |

320KG |

400KG |

580KG |

750KG |

1250KG |

1600KG |

2400KG |

KRY 0℃~+100℃ 6S

| Modelo |

KRY-A25W/6S |

KRY-A38W/6S |

KRY-A60W/6S |

| Gama de temperaturas |

0℃~+100℃ |

| Precisão do controle de temperatura |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

| Precisão do controlo do caudal/Grupo |

2~25 L/min |

2~25 L/min |

2~25 L/min |

| Precisão da vazão/grupo |

±0.2L/min |

| Número de grupos de saída de fluido |

6 grupos |

6 grupos |

6 grupos |

| Controle de pressão/grupo |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Capacidade de aquecimento |

15kW |

25kW |

38kW |

| Capacidade de resfriamento |

100℃ |

25kW |

38kW |

60kW |

| 20℃ |

25kW |

38kW |

60kW |

| 5℃ |

18kW |

27kW |

42kW |

| Water-cooled type Wat 20度 |

6000L/H

DN32 |

9000L/H

DN40 |

15000L/H

DN50 |

| Potência 380V50HZ |

38kW |

55kW |

82kW |

| Dimensão(cm) |

200*145*205 |

200*145*205 |

200*145*205 |

| Peso |

900 kg |

1200kg |

1950kg |

Frequency Conversion Series

KRYZ -40℃~+100℃

| Modelo |

KRYZ-475

KRYZ-475W |

KRYZ-4A15W |

KRYZ-4A25W |

| Gama de temperaturas |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

| Precisão do controle de temperatura |

±0.1℃ |

±0.1℃ |

±0.1℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

| Saída do caudal |

1~25 L/min |

1~25 L/min |

1~25 L/min |

| Precisão do caudal |

±0.1 L/min |

±0.1 L/min |

±0.1 L/min |

| Potência de aquecimento |

7,5 kW |

15kW |

25kW |

refrigeração

capacidade |

100℃ |

7,5 kW |

15kW |

25kW |

| 20℃ |

7,5 kW |

15kW |

25kW |

| 0℃ |

7,5 kW |

15kW |

25kW |

| -20℃ |

4,5 kW |

10kW |

16kW |

| -35℃ |

1,8kW |

4kW |

6,5 kW |

| Tamanho da conexão |

G3/4 |

G3/4 |

G3/4 |

| Water-cooled At20℃ |

2500L/H

ZG3/4 |

4000L/H

ZG1 |

6000L/H

DN32 |

| Potência 380V50HZ |

14kW |

25kW |

38kW |

| Dimensão(cm) |

55*85*175 |

70*100*175 |

80*120*185 |

| Peso |

280kg |

360 kg |

620kg |

| Opcional |

Extended to -40 ℃~+135 ℃ |

KRYZ -40℃~+100℃ 2T

| Modelo |

KRYZ-475W/2T |

KRYZ-4A15W/2T |

KRYZ-4A25W/2T |

| Gama de temperaturas |

-40℃~+100℃ |

| Precisão do controle de temperatura |

±0.1℃ |

±0.1℃ |

±0.1℃ |

| Feedback da temperatura |

Pt100 |

Pt100 |

Pt100 |

| Exibição de temperatura |

0.01k |

0.01k |

0.01k |

| Saída do caudal |

1~25 L/min |

1~25 L/min |

1~25 L/min |

| Precisão do controlo do caudal/Grupo |

±0.1 L/min |

±0.1 L/min |

±0.1 L/min |

| Número de grupos de saída de fluido |

2 grupos |

2 grupos |

2 grupos |

| Controle de pressão/grupo |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Potência de aquecimento |

7.5kW*2 |

10kW*2 |

15kW*2 |

refrigeração

capacidade |

100℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

| 20℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

| 0℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

| -20℃ |

4.5kW*2 |

8.5kW*2 |

14kW*2 |

| -35℃ |

1.8kW*2 |

4kW*2 |

6.5kW*2 |

| Water-cooled At20℃ |

4000L/H

ZG1 |

8000L/H

DN32 |

12000L/H

DN40 |

| Dimensão(cm) |

80*120*185 |

100*150*185 |

200*145*205 |

| Potência 380V50HZ |

28kW |

45kW |

70kW |

| Peso |

660KG |

850 kg |

1350kg |

| Opcional |

Extended to -40 ℃~+135 ℃ |

| Hourly power consumption kWh |

-40℃ |

-10℃ |

20℃ |

| KRY-475 |

5 |

6.2 |

8.4 |

| KRYZ-475 |

2.2 |

4 |

4.8 |

| Frequency conversion saves power consumption |

56% |

35% |

43% |

| Explain |

1. Empty load test data; 2. The test condition is an ambient temperature of 20 ℃; 3. Flow rate 15L/min |

Oil cooling chiller for motor test

KRYZ 0℃~+160℃

| Modelo |

KRYO-A15W |

KRYO-A25W |

KRYO-A38W |

KRYO-A15W2S |

KRYO-A25W2S |

KRYO-A38W2S |

| Gama de temperaturas |

0℃ ~ +160℃ Different viscosity oils have different temperature ranges |

| Precisão do controle de temperatura |

±0.3℃ |

| Precisão do caudal |

±0.2L/min |

| Controlo da pressão |

0,2bar~2,5bar |

| Potência de aquecimento |

15kW |

25kW |

38kW |

15kW |

25kW |

38kW |

refrigeração

capacidade |

125℃ |

15kW |

25kW |

38kW |

15kW |

25kW |

38kW |

| 20℃ |

12kW |

20kW |

30kW |

12kW |

20kW |

30kW |

| refrigerante |

R410A |

| Refrigerante secundário |

Óleo |

| Tamanho da conexão |

G3/4 |

| Water-cooled At20℃ |

3000L/H |

4200L/H |

6200L/H |

3000L/H |

4200L/H |

6200L/H |

| Tamanho da conexão |

G3/4 |

G3/4 |

G1 |

G3/4 |

G3/4 |

G1 |

direct cooling heating series

Can meet the direct cooling/direct heating for battery pack and vehicle testing and testing. This equipment is mainly used for cooling and heating capacity testing. It uses variable frequency compressor with adjustable output;

KRYZ 0℃~+160℃

| Modelo |

KRYZ-5W-ZLH |

KRYZ-5W-ZL |

| KRYZ-5-ZLH |

KRYZ-5-ZL |

| Capacidade de resfriamento |

0.5kW~10kW |

0.5kW~10kW |

| Capacidade de aquecimento |

0.5kW~10kW |

|

| Grau de subresfriamento |

Refrigeração 0k~8K

Aquecimento a 0k~6k em ambiente de baixa temperatura, 6k~20k |

Refrigeração 0k~8K |

| Overheating degree |

Refrigeration 2k~20k

Heating 2k~10k |

Refrigeration 2k~20k |

| Precisão do controle de pressão de condensação |

Better than ±50kpa |

Better than ±50kpa |

| Pressão de sucção |

300kpa~600kpa ±10kpa |

300kpa~600kpa ±10kpa |

| Temperatura do ambiente de teste do pacote de baterias |

-40℃~50℃ |

-40℃~50℃ |

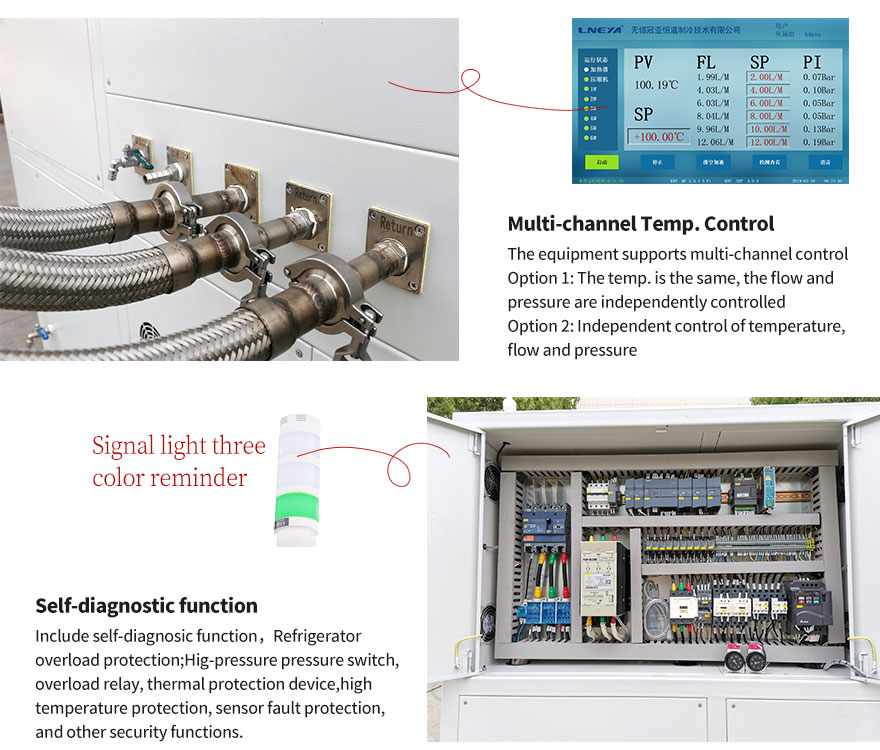

multi-channel independent temperature control

Adopts LNEYA PLC control, simple menu navigation, 7″ color large screen, multi-faceted and multi-functional images to display comprehensive important data information. The newly added safety measures ensure continuous unattended operation. All relevant operating status data are continuously monitored and visualized on the touch screen. Supports one-to-many multi-channel independent control, and each group can be set independently.

Appearance details

Application cases

The testing unit needs to use specific temperature change curves and record temperature changes; The temperature range is usually -40 ℃ to 100 ℃ (can expand to 150 ℃); When conducting tolerance testing, it is usually done in an infinite cycle.

High adaptability and wide applicationS

Suitable for more simulation test temperature control

Equipment application: new energy battery pack, battery module, battery cell, motor and controller, charger, DC/DC converter, electronic pump

SOLICITAR UM ORÇAMENTO

Produtos recomendados

Temperature Control :-5℃~-150℃

Controlo da temperatura para vários reactores, sistemas de destilação ou extracção, laboratórios, institutos de investigação, indústrias químicas, farmacêuticas, petroquímicas, bioquímicas, médicas, hospitalares, oficinas de investigação e desenvolvimento, testes de semicondutores, aeroespacial, biologia.

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Temperature Control: -40℃~100℃

Simulação de temperatura para o teste de qualidade do veículo: teste da duração da bateria, banco de ensaio do injetor/motor de combustível, teste do airbag, banco de ensaio de componentes, etc. Pode simular as condições ambientais externas na câmara climática ou substituir o sistema interno, o que pode criar as condições de temperatura reais necessárias para o banco de ensaio.

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor