Vehicle high temperature and high humidity test vehicle anti-aging performance

On test benches in the automotive industry, accurate temperature simulation is critical. From the time of the test, the air temperature in the test chamber has always been maintained at 45 ℃, which is equivalent to the hottest area of the Flaming Mountains in Turpan, Xinjiang, China. Ultra-high temperature environments cause all automotive components, from control electronics to gaskets and load-bearing elements, to experience severe temperature fluctuations that, in addition to mileage, stress materials and circuits. Temperature control systems are mainly used in two ways: they can simulate external environmental conditions in a climate chamber or replace internal systems, such as the cooling circuit of an engine. For example in a vehicle, a coolant is supplied to the sample.

IC test conditions for locomotives: -40℃~125℃, wind blowing, sun exposure, high vibration;

Instrument panel operation test test conditions: -40℃~85℃;

Motor controller test conditions: operating test temperature: 40 ℃ ~ 110 ℃;

Satellite positioning (GPS) Test conditions: high temperature operation test temperature: 85℃; low temperature operation test temperature: -40℃;

Compound vibration: -40℃~80℃;

The only area in my country that meets the ambient temperature tested by these projects is Turpan, with a large temperature difference between day and night. Shipping is a big project. Obviously the best solution is for the test house to have temperature simulation system equipment.

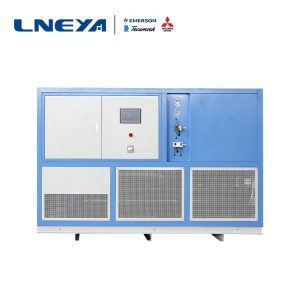

Our refrigeration and heating temperature control flow system KRY series equipment can be flexibly connected to other test platforms. The system is controlled by Siemens PLC, and the electrical control part can complete all actions without manual operation, which not only avoids human operation errors but also improves the The accuracy of the test results has a great advantage in endurance testing. The temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. The equipment can control the flow and pressure independently while controlling the temperature, and different customized solutions are required for simultaneous control.

Recomendações relacionadas

-

-80 °C pontos do equipamento de funcionamento do fabricante do frigorífico

1560Quando o utilizador escolhe o frigorífico de -80 °C, é definitivamente necessário ter uma qualidade fiável. O frigorífico Wuxi Guanya (LNEYA)-80 °C deve prestar atenção aos seus detalhes de funcionamento durante a operação para evitar a falha do equipamento causada por...

Ver detalhes -

Dispositivo de arrefecimento do dispositivo de arrefecimento de teste de baterias de energia nova avaliação de falhas do compressor

1755Como identificar os três terminais na caixa do compressor totalmente fechada da unidade de arrefecimento de teste da bateria de energia nova? A resistência entre o terminal de funcionamento (R), o terminal de arranque (S), o terminal comum (C) e o RS é maior do que a resistência...

Ver detalhes -

Como lidar com o congelamento do frigorífico?

1929Existem muitos tipos de chillers, e os clientes familiarizados com esta peça estão definitivamente familiarizados com o chiller. Para a cobertura do refrigerador, muitas pessoas são ignorantes, e então vamos aprender mais sobre isso com LNEYA! 1. Se é um refrigerador, por favor...

Ver detalhes -

Instruções de seleção do arrefecedor de reator de 500 litros

1618O chiller para reator de 500 litros é mais utilizado na indústria farmacêutica. Portanto, o usuário precisa selecionar um fabricante regular ao selecionar e, ao mesmo tempo, entender os recursos e a configuração. Para a seleção de 500 litros de r...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor