What should do if the equipment of the thermal shock test chamber does not reach the set temperature

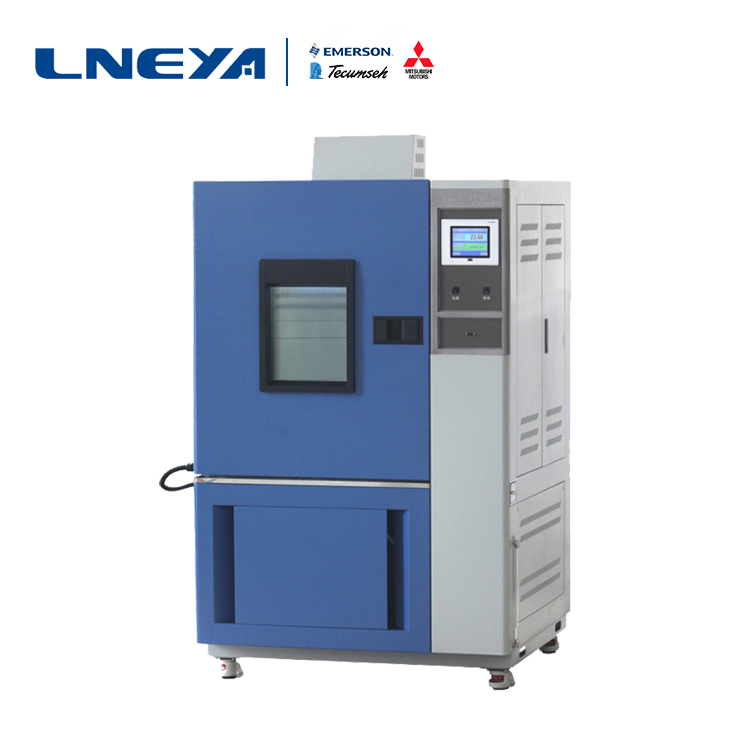

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Recomendações relacionadas

-

Instruções de fuga interna do frigorífico de temperatura ultra baixa à prova de explosão

18551. Sound leak detection method: First, the refrigeration pipeline of the explosion-proof ultra-low temperature refrigerator is filled with nitrogen. Then use a stethoscope to check the interior. When you hear a leak in a certain area, mark it. Car...

Ver detalhes -

Introdução à solução mista de sistemas de refrigeração com glicol (refrigeradores de glicol)

1480Os refrigeradores de glicol são sistemas de refrigeração industrial que utilizam um tipo de anticongelante chamado glicol, misturado com água, para baixar o ponto de congelação na aplicação do sistema de refrigeração. O glicol é uma classe de compostos orgânicos que pertencem ao grupo ...

Ver detalhes -

What are the temperature control performance of laboratory recirculating chillers

1717The laboratory recirculating chiller is atypical cooling circulator with heating function to ensure the repeatability oflaboratory results. There are water-cooled or air-cooled refrigerators, whichcan be placed in a laboratory fume hood or set ...

Ver detalhes -

What are the factors related to the selection of heating and refrigeration circulators?

1664Heating and refrigeration circulators are used in many laboratory projects. They are usually equipped with reactors and reactors for cooling, heating and temperature control. Then, what factors are related to the selection of heating and cooling i...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor