Condições específicas do ensaio a alta e baixa temperatura da bateria do VE (veículo elétrico)

There are mainly 2 types of vehicles:

1. Battery for pure electric vehicle

2. Fuel cell, dedicated to fuel cell electric vehicles

Thermal test: This test is performed to characterize the reaction of cells to the high-temperature environment.

a) Adjust the SOC of battery to 100% of BEV application and 80% of HEV application.

b) Batteries stabilized at room temperature shall be placed in a gravity or circulating air convection oven. The oven temperature shall be raised to 130 ℃ ± 2K at the speed of 5K/min. The battery shall be held at this temperature for 30 minutes before stopping the test.

Teste de ciclo de temperatura:

This test is conducted to characterize the thermal durability of the battery by alternately exposing it to low and high temperatures to cause expansion and contraction of the battery components.

a) Adjust the SOC of battery to 100% of BEV application and 80% of HEV application.

b) Conduct temperature cycling according to ISO 16750-4. As shown in Table 4, the ultra-low operating temperature shall be – 40 ℃ or Tmin specified by the battery manufacturer, and the maximum operating temperature shall be 85 ℃ or Tmax specified by the battery manufacturer. Perform 30 test cycles as specified.

The battery shall be heated in a gravity convection or circulating air oven with an initial temperature of 20 ± 5 ° C (68 ± 9 ° F). The temperature of the oven is raised to 130 ± 2 ℃ (266 ± 3.6 ℉) at the rate of 5 ± 2 ℃ (9 ± 3.6 ℉) per minute and maintained for 10 minutes. The sample shall be returned to room temperature (20 ± 5 ℃) and then checked. For batteries with a set temperature higher than 100 ℃ (212 ℉), the regulating temperature shall be increased from 130 ± 2 ℃ (266 ± 3.6 ℉) to 30 ± 2 ℃ (86 ± 3.6 ℉) from the manufacturer’s maximum specified temperature. For lithium metal chemical battery, the regulating temperature shall be increased to 170 ± 2 ℃ (338 ± 3.6 ℉) at most.

The above contents are excerpts from the network. Please contact us if you have any questions.

Recomendações relacionadas

-

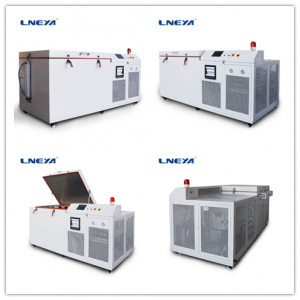

Descrição do congelador industrial de temperatura ultra baixa LNEYA

1840LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

Ver detalhes -

Como escolher o sistema de controlo da temperatura de arrefecimento e aquecimento?

1744O preço do sistema de controlo da temperatura do aquecimento por refrigeração não é o fator principal. O objetivo principal é implementar a tecnologia de controlo da temperatura através da função de controlo da temperatura. No entanto, não é o sistema de controlo da temperatura que...

Ver detalhes -

Fluxo de trabalho e composição do equipamento de refinação e desparafinagem de petróleo

1614The oil dewaxing process is based on the melting point difference between the wax and the oil and the solubility of the wax in the oil becomes smaller as the temperature decreases, and the crystalline wax is precipitated by cooling. Then through t...

Ver detalhes -

What are the effects of the oil separator on the equipment analyzed by the chiller manufacturer

1358Oil separators use more accessories in thechiller refrigeration system. So as users, we need to understand where the mainimpact is in order to better use the equipment.In the configuration of the chiller, theposition of the oil separator is aft...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor