Etapas de manutenção da máquina do ciclo de aquecimento e arrefecimento do óleo de silicone a alta temperatura

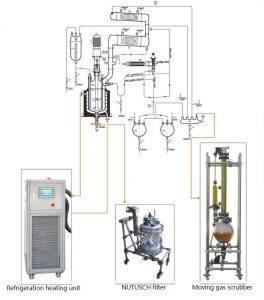

The mechanical wear of the high temperature silicone oil cooling and heating cycle machine is an important factor that directly affects the refrigeration capacity. It is necessary to record the operating parameters during use, often listen to the sound during the operation, and check the refrigerant and refrigerating oil. Troubleshoot based on this, regular maintenance and maintenance, so that when the high-temperature silicone oil cooling and heating cycle machine fails, the maintenance personnel can quickly find the problem and eliminate the fault by referring to the recorded parameters.

Maintenance steps:

1. Discharge the refrigerant in the industrial chilled system: the needle valve is kept on the suction side of the industrial explosion-proof low-temperature refrigerator, the three-way valve is connected to the needle valve, the operating valve is opened, and the inside of the refrigerator is cooled. All reagents in the industrial refrigerator system have been discharged;

2. Replace the faulty parts of the high-temperature silicone oil cooling and heating cycle machine: If you know which parts are faulty, please directly replace the faulty parts;

3. Nitrogen flushing and pressure test: Nitrogen is still injected through the needle valve on the suction side of the industrial high-temperature silicon oil cooling and heating cycle machine;

4. Vacuum: After the pressure test, the industrial refrigerator needs to be vacuum cleaned to ensure that there is no problem;

5. Refrigerant filling: There are two filling methods for the refrigerant in the high-temperature cooling and heating cycle machine, namely the low-pressure side filling method and the high-pressure side filling method;

6. Test run: After completing the above steps, please test run the high-temperature silicone oil cooling and heating cycle machine to ensure that there is no problem;

After completing the maintenance of the high-temperature silicone oil cooling and heating cycle machine and troubleshooting, the performance of the corresponding parts will be tested to ensure the reliable and stable operation of the equipment.

Recomendações relacionadas

-

Sistema WFI farmacêutico circulador/resfriador de água de arrefecimento a baixa temperatura

1410O sistema WFI (Water for Injection) na indústria farmacêutica é um sistema de água altamente purificada que fornece água estéril que cumpre normas de qualidade rigorosas para a produção de medicamentos e formulações (como injecções). ...

Ver detalhes -

Existem normalmente três formas de controlar a temperatura dos reactores de laboratório

14841. Controlo manual: Operar manualmente o botão na frente do controlador do reator.2. Controlo por PC: O PC e o controlador estão ligados por um cabo de rede, e a operação é efectuada no PC.3. Controlo por termóstato: Óleo de silicone...

Ver detalhes -

How to troubleshoot the failure of the material aging test chiller?

1768Regular maintenance work for the material aging test chiller, and troubleshooting is also very important. 1. Exhaust at double high pressure, heat dissipation may be problematic. When it is detected that the high and low pressure of the system are...

Ver detalhes -

O equipamento profissional de alta qualidade ajuda o laboratório a produzir resultados infinitos

2857Nos últimos anos, a economia da China continuou a crescer. Sob a oportunidade de desenvolvimento de máquinas profissionais integradas de alta e baixa temperatura, as realizações científicas e tecnológicas de laboratório também estão em desenvolvimento sustentável. LNEYA...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor