How to troubleshoot the failure of the material aging test chiller?

Regular maintenance work for the material aging test chiller, and troubleshooting is also very important.

1. Exhaust at double high pressure, heat dissipation may be problematic.

When it is detected that the high and low pressure of the system are higher than normal, it is usually because there is air in the system or excessive refrigerant is added. At this time, it is necessary to re-evacuate and add an appropriate amount of refrigerant to solve the problem. However, there is another situation, that is, poor heat dissipation, especially when the ambient temperature is relatively high, which often leads to worse heat dissipation. The cause of this failure is generally that the heat sink is blocked, dirty, and the speed of the heat dissipation fan is not enough.

2. Refrigerant with low pressure loss, otherwise the system will be blocked.

When the high and low pressures are both low, there are two possibilities:

(1) If the system is blocked, the blocked part will produce throttling, and there will be a significant temperature difference in the throttling part, and the problem can be found by feeling it with your hands.

(2) The leakage of refrigerant leads to insufficient refrigerant. This situation is more common. At this time, the material aging test cooler detector must be used to find out the leaking location and perform replacement.

3. Low pressure, high pressure, low pressure, replace the compressor.

When the material aging test cooler pressure gauge detects that the low pressure is higher than normal, and the high pressure is lower than normal, at this time, it is recommended that the chiller refrigeration cannot achieve the effect of the normal material aging test refrigerador. The reason is likely to be the wear and tear in the material aging test refrigerador pump, resulting in a drop in power. At this time, it is often necessary to replace the compressor to solve the problem.

4. There is water vapor in the meter shake system, so it must be changed when it is timed out.

When the material aging test cooling machine system is working, if the pressure gauge needle keeps shaking, it means that there is moisture in the system. To solve this problem, it is generally necessary to re-evacuate, and the pumping time must be no less than 15 minutes. If necessary, the drying bottle needs to be replaced to drain the water in the system.

Recomendações relacionadas

-

Teste de semicondutores Unidade de circulação de aquecimento de duplo canal

1327O ciclador de aquecimento de canal duplo em ensaios de semicondutores refere-se a um dispositivo utilizado para ensaiar dispositivos semicondutores (como semicondutores de potência), que pode controlar simultaneamente dois canais de ensaio independentes para efetuar o aquecimento e o arrefecimento...

Ver detalhes -

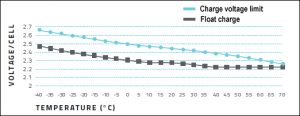

É correto prolongar a duração da bateria baixando a temperatura ambiente?

1538The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Ver detalhes -

Adição de investimento no mercado da unidade de recuperação de condensados de gás COV para criar energia verde no sector

1676In recent years, due to the deteriorating atmospheric environment and various environmental problems, people are paying more and more attention to the emission of volatile organic gases in the atmosphere. Volatile organic compounds, also known as ...

Ver detalhes -

A diferença entre a tecnologia de arrefecimento líquido por contacto direto e a tecnologia de arrefecimento líquido por placa fria

2009A tecnologia de arrefecimento por líquido de placa fria é um método de implementação em que o calor dos componentes de aquecimento é indiretamente transferido para o líquido de arrefecimento contido na tubagem de circulação através da placa fria, e o calor é...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor