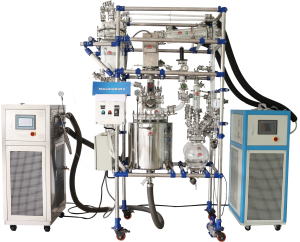

Reactor temperature control unit TCU with PID control loop

LNEYA reaction kettle temperature control unit tcu adopts PID control loop, which has certain applications in many fields. The reaction kettle temperature control unit tcu of PID control loop adopts fully closed cycle refrigeration system, with fast cooling and heating speed and low noise.

The reaction tank temperature control unit tcu of the PID control loop can achieve a dynamic temperature control of -120 degrees to 300 degrees. The system uses existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration To a single-fluid system or a secondary circuit that controls the temperature of the process equipment. This completes that only one heat-conducting liquid flows into the jacket of the reaction vessel (instead of direct steam, cooling water or ultra-low temperature liquid).

The reaction tank temperature control unit tcu of the high-precision PID control circuit is a high-precision constant temperature source with built-in cooling and heating. It can be used in the matching reaction kettle for constant temperature experiments, or connected to other equipment through a hose as a constant temperature source. The reaction tank temperature control unit tcu of PID control loop is widely used in petroleum, chemical industry, electronic instrumentation, physics, chemistry, biological engineering, medicine and health, life sciences, light industry food, physical property testing and chemical analysis and other research departments, colleges and universities, Enterprise quality inspection and production department.

The reaction tank temperature control unit tcu of the PID control circuit adopts high-precision PID program to control the temperature, which can directly heat and cool, and can also be used as a heat source or cold source for auxiliary heating and auxiliary cooling. It is used for chemical reaction process control in petrochemical, pharmaceutical and other For thermostats or external circulation applications of reaction kettles, automatic synthesis instruments, extraction and condensation devices, high-pressure protection and high-temperature protection of refrigeration and heating systems ensure long-term operation of the instrument.

In the practical application of the reaction tank temperature control unit tcu of the PID control circuit, in order to effectively guarantee the service life of the equipment and reduce the failure rate in use, as an operator, it is necessary to understand some necessary reaction tank temperature control units of the PID control circuit. tcu failure processing method, in order to better and more safely use the reactor temperature control unit tcu of the PID control loop.

Recomendações relacionadas

-

Quais são os componentes que melhoram o desempenho dos chillers industriais?

1855Os refrigeradores industriais são equipamentos indispensáveis na produção de LNEYA. Com o seu funcionamento normal, teremos melhor eficiência de trabalho e maior qualidade do produto. O sistema de refrigeração de um resfriador industrial é composto principalmente de quatro compo...

Ver detalhes -

What is the temperature control of the reactor?

1852The reactor cooling system is one of the common equipment in the chemical industry. It can not only heat but also refrigerate to meet the needs of heating and cooling in the reaction process. There are usually three ways to control the temperatu...

Ver detalhes -

O que causa sedimentos na utilização do refrigerador?

1402Um refrigerador é uma unidade arrefecida a água que utiliza a circulação da água para fornecer uma temperatura constante, um caudal constante e uma pressão constante da água de arrefecimento. O sistema de água fria LNEYA tem o seu próprio princípio de funcionamento, ou seja, uma certa quantidade de água é injecta...

Ver detalhes -

Método de funcionamento do sistema de circulação de alta e baixa temperatura de revestimento por vácuo

2042Em muitas experiências químicas actuais, o sistema de circulação de alta e baixa temperatura de revestimento a vácuo pode ser utilizado, fazendo com que o sistema de aquecimento por refrigeração de alta e baixa temperatura apoie o sistema de revestimento a vácuo, e a operação seja mais eficiente.

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor