Quais são os componentes que melhoram o desempenho dos chillers industriais?

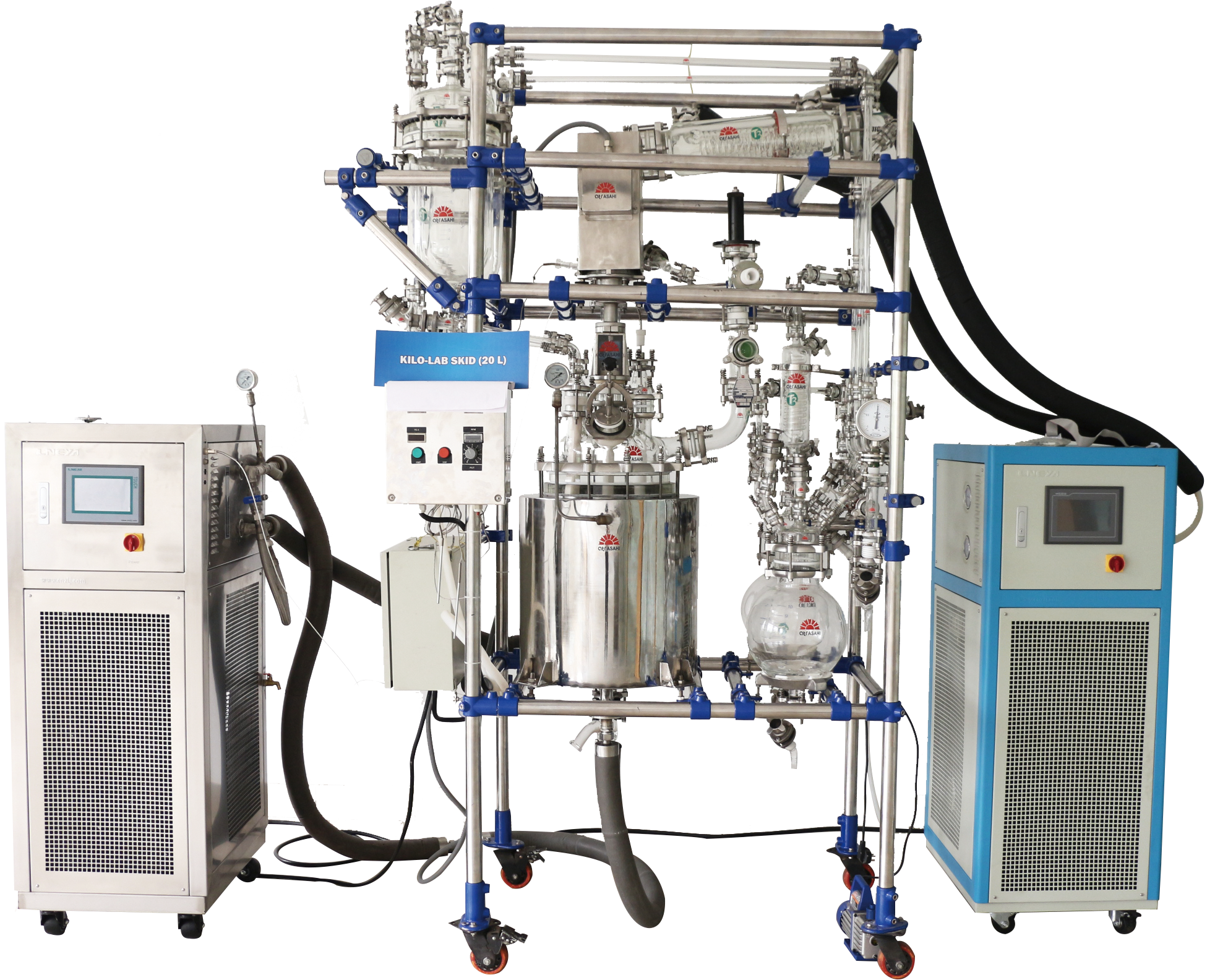

Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core components: compressor, condenser, expansion valve and evaporator. On this basis, in order to improve the performance of industrial chillers, there are usually some auxiliary components.

(1) Compressors for industrial chillers:

It is the core of the entire chiller. Its quality is enough to affect the quality of a machine, and even the length of its lifespan. The compressor is the power source to ensure refrigeration. The compressor is used to increase the refrigeration pressure in the system, so that the refrigerant circulates in the refrigeration system to achieve the purpose of refrigeration. Common compressor types are open, semi-hermetic and fully-hermetic. Generally, the chiller with chilled water above 0°C adopts a fully hermetic compressor. If the chilled water is below 0°C, the low-temperature chiller uses a semi-hermetic compressor, while the open type is generally used in the refrigeration system with ammonia as the refrigerant.

(2) Condenser of industrial chiller:

It is the high temperature and high pressure Freon of the refrigeration system. After coming out of the compressor, it enters the condenser, releasing a lot of heat to the cooling medium, cooling and liquefying. There are three common types: water-cooled, air-cooled and evaporative. We mainly talk about water-cooled condensers. In a water-cooled condenser, the heat given off by the refrigerant is carried away by the cooling water. The cooling water can be flowed once or recycled. When using circulating water, cooling towers or cold pools are required. Water-cooled condensers have shell and tube, casing, immersion and other structural forms.

(3) Industrial chiller evaporator:

When the freon liquid in the refrigeration system enters the expansion valve and is sent to the evaporator, it belongs to the vaporization process. At this time, a large amount of heat needs to be absorbed, so that the temperature of the cooled medium is gradually lowered, so as to achieve the effect of cooling and cooling. According to the type of cooling medium, it is divided into two categories: cooling liquid (water) evaporator and cooling air evaporator.

(4) Industrial chiller expansion valve:

It is a throttling and pressure-reducing component that reduces the condensation pressure of the refrigerant to the evaporating pressure, so it is an essential component in the refrigeration system. It is called the four major components of the refrigeration system together with the compressor, the evaporator and the condenser.

Recomendações relacionadas

-

O sistema de refrigeração de um refrigerador criogénico

1615Nos últimos anos, os produtos de refrigeração criogénica são cada vez mais comuns no mercado industrial nacional. Muitas produções industriais precisam de mais ajuda dos produtos de resfriamento criogênico para alcançar o ambiente ideal de baixa temperatura. Por isso, os produtos criogénicos...

Ver detalhes -

Que processo no fabrico de semicondutores requer um refrigerador multicanal? Porque é que é necessário?

1535Chemical Vapor Deposition (CVD): In the CVD process, a multi-channel chiller is used to cool the reaction chamber walls, heat exchangers, and gas preheating exchangers to maintain stable reaction chamber temperature, ensuring precise contro...

Ver detalhes -

How to solve the common faults of industrial circulating chillers?

1700For industrial circulating chillers, if they are always in a high-temperature operating state, a large amount of cold air will be seriously lost. After ensuring the sealing effect of the use environment, effective thermal insulation can be carried...

Ver detalhes -

Quais são as condições da reação de descarboxilação e o controlo da temperatura do processo?

1817A descarboxilação dos ácidos aromáticos é mais fácil do que a dos ácidos gordos. Por exemplo, o ácido benzoico pode ser descarboxilado adicionando um pouco de pó de cobre como catalisador numa solução de quinolina e aquecendo. Quando um grupo fortemente retirador de electrões é...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor