Precauções para a instalação de um refrigerador especial para ensaios de energia nova

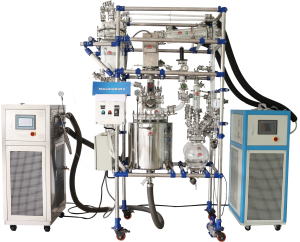

The installation of the special chiller for new energy testing is an important link before operation. The quality of the installation is directly related to the operation and operation status of the special chiller for new energy testing. So, what should be paid attention to in the installation of the special chiller for new energy testing?

If the special chiller for new energy test adopts semi-hermetic or fully-hermetic compressor, an oil separator should be installed, and an appropriate amount of oil should be added to the installed oil separator. When the evaporation temperature is lower than -15 degrees, a gas-liquid should be installed. Separator and add appropriate amount of refrigeration oil. Secondly, the compressor base should be installed with a shock-absorbing rubber seat, and the installation of the special chiller for new energy testing should leave a maintenance space to facilitate the observation of the adjustment of instruments and valves.

The high pressure gauge of the special chiller for new energy testing should be installed at the tee of the liquid storage and filling valve. The overall layout of the special chiller for new energy testing is reasonable and the color is the same. The installation structure of each type of unit should be consistent.

When debugging the special chiller for new energy test, it is necessary to pay attention to measuring the power supply voltage, measuring the resistance value of the three windings of the compressor and the insulation of the motor, checking the opening and closing of each valve of the refrigeration system, and pouring the refrigerant into the storage liquid to the standard charge after evacuation. 70%-80% of the filling volume, and then run the compressor, add air from low pressure to enough volume.

After the special chiller for new energy test is turned on, first listen to whether the sound of the compressor is normal, check whether the condenser and air cooler are running normally, and whether the three-phase current of the compressor is stable. After the special chiller for new energy test cools down smoothly, check the exhaust pressure, suction pressure, exhaust temperature, suction temperature, motor temperature, crankcase temperature, and expansion valve temperature in the refrigeration system, and observe the frosting of the evaporator and expansion valve. , observe the oil level and color change of the oil glass. Check whether the sound of the special chiller for new energy testing is abnormal.

Another point is that the special chiller for new energy testing needs to pay more attention to its maintenance knowledge and carry out a lot of related maintenance work.

Recomendações relacionadas

-

Quais são os componentes que melhoram o desempenho dos chillers industriais?

1851Os refrigeradores industriais são equipamentos indispensáveis na produção de LNEYA. Com o seu funcionamento normal, teremos melhor eficiência de trabalho e maior qualidade do produto. O sistema de refrigeração de um resfriador industrial é composto principalmente de quatro compo...

Ver detalhes -

quais são as causas do entupimento do refrigerador

1394O refrigerador é uma parte muito importante do compressor de ar de parafuso. A principal função é arrefecer o óleo lubrificante do compressor de ar e o ar comprimido. Se estiver bloqueado, a temperatura aumentará. Uma das principais causas de falha do compressor de ar...

Ver detalhes -

Shutdown method in the case of high-precision high-low temperature circulator failure

1846The high-precision high-low temperature circulator is one of the equipments used in the pharmaceutical and chemical industry to support various reactors. If users encounter an abnormal power outage during use, they should pay attention to operatio...

Ver detalhes -

Vantagens do chiller de recirculação de arrefecimento a baixa temperatura

1392O chiller de recirculação de resfriamento de baixa temperatura é um tipo de refrigeração usando compressor, e a bomba de circulação fornece fonte fria para manter a faixa de temperatura de - 2 5 ℃ a 30 ℃. O chiller de recirculação de refrigeração tem uma economia de espaço ...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor