Porque é que os gases especiais utilizados nos processos de fabrico de semicondutores requerem refrigeradores?

If you have any questions, please contact us

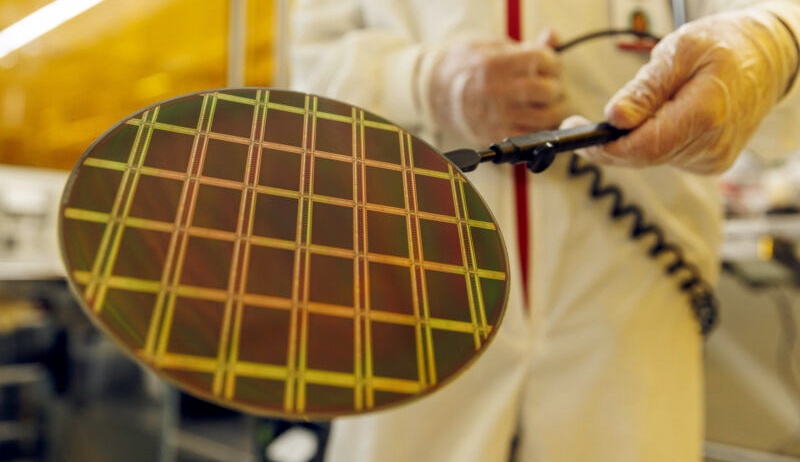

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

Oferecer 7 * 24 consultas gratuitas e soluções abrangentes

Recomendações relacionadas

-

Wuxi Guanya analisa como julgar as condições de refrigeração do resfriador de água refrigerada para você

1371Ao comprar um refrigerador de água refrigerada, se você quiser saber a qualidade dos chillers, você pode ver a condição de refrigeração dos chillers. O efeito de refrigeração dos bons chillers é relativamente estável e eficiente em operações de longo prazo...

Ver detalhes -

Instruções de manutenção de inverno da máquina quente e fria à prova de explosão

1976Quando a máquina integrada quente e fria do tipo à prova de explosão é utilizada no final do dia ou quando não é utilizada em modo de espera, certifique-se de que desliga o tubo de ligação da água de arrefecimento, limpa a água de arrefecimento restante no tubo e armazena-a...

Ver detalhes -

O princípio de refrigeração do sistema de refrigeração de glicol

1691Por vezes, o transportador de refrigerante precisa de atingir uma temperatura inferior a 0 C. Se o gelo estiver a transportar o cozinheiro, este irá congelar, pelo que a adição de algum líquido anticongelante pode evitar o congelamento, e o glicol pode evitar o congelamento.

Ver detalhes -

The reason for the poor cooling effect of the air-cooled chiller of the semiconductor heat sink ther

1713Semiconductor heat sink constanttemperature table Air-cooled chiller is one of the equipment for temperaturecontrol in the semiconductor industry. If the cooling effect is not good, itwill affect the use.The occurrence of this situation is rela...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor

Submeter para consulta

Responder-lhe-emos no prazo de 24 horas