Os fabricantes de congeladores a -20 ° C escolhem o que olhar para o evaporador?

In the process of producing industrial freezer, the selection of a suitable evaporator is also very important for the freezer, because the choice of suitable evaporator is better for better operation of the -20 °C freezer.

The evaporator is generally equipped with a -20 °C freezer, and the user does not have to choose. However, in order to better maintain the refrigeration system and ensure its efficient operation, some factors should be noted. Due to the influence of the height of the refrigerant liquid column of the -20 °C freezer manufacturer, the evaporation temperature at the bottom of the full liquid evaporator is higher than the evaporation temperature of the liquid surface. Different refrigerants have different effects on the evaporating temperature of different liquid levels due to the height of the hydrostatic fluid. Regardless of the refrigerant, the lower the evaporation temperature of the liquid surface, the greater the effect of the hydrostatic height on the evaporation temperature. Therefore, the effect of the hydrostatic height on the evaporation temperature can be ignored only when the evaporation pressure is high. When the evaporation temperature is low, it cannot be ignored. That is to say, it is uneconomical to use a full liquid evaporator at this time.

If the -20 ° C freezer evaporating temperature is lower than the brine solidification temperature, the brine may freeze. In one process of the brine, the temperature of the brine is low and the possibility of freezing is relatively large. When water is used as the brine, it is theoretically possible that the inner wall temperature of the tube can be as low as 0 °C. However, for safety reasons, the inner wall temperature of the tube at the outlet end of a process is usually maintained above 0.5 °C. In the case of brine as a coolant, according to the same principle, the inner wall temperature of the pipe should be higher than the solidification temperature of the brine by more than 1 °C.

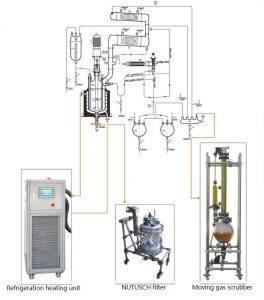

When the -20 °C freezer refrigerant flows through the evaporator, the pressure loss is caused, and the pressure p2 of the refrigerant at the outlet of the evaporator is inevitably lower than the pressure p1 at the inlet, thereby lowering the suction pressure of the compressor, resulting in a decrease in the refrigeration capacity. According to different models, the choice of evaporator is different, such as box type freezer, using water tank coil evaporator; open type freezer and screw type freezer, use shell and tube evaporator; Acid-base freezer, you can choose titanium tube evaporator or stainless steel plate exchanger, of course, can be customized according to user needs.

In general, manufacturers have certain principles in selecting evaporators. Basically, brand evaporators are one of the manufacturers’ choices.

Recomendações relacionadas

-

Operating Principle of LNEYA Industrial Air Cooled Chillers

2110Industrial Air Cooled Chillers is a heatexchanger which USES air to cool the hot fluid. The hot fluid in the tube isheated through the exchange of heat between the tube wall, the fin and theoutside air, which is usually supplied by the ventilat...

Ver detalhes -

Como evitar que a pressão de congelação da caixa de congelação rápida de rolamentos seja demasiado baixa?

1823No sistema de refrigeração do chiller de rolamento, se a instalação do condensador não estiver no espaço fechado, a pressão de escape do sistema (pressão de condensação) tende a ser menor no inverno (ou baixa temperatura), o que é muitas vezes mais commo...

Ver detalhes -

O equipamento profissional de alta qualidade ajuda o laboratório a produzir resultados infinitos

2860Nos últimos anos, a economia da China continuou a crescer. Sob a oportunidade de desenvolvimento de máquinas profissionais integradas de alta e baixa temperatura, as realizações científicas e tecnológicas de laboratório também estão em desenvolvimento sustentável. LNEYA...

Ver detalhes -

Partilha de conhecimentos sobre a seleção e manutenção de refrigeradores

1726Os chillers podem ser usados em muitas indústrias, mas quem é o melhor fabricante de chillers de baixa temperatura nos principais fabricantes de chillers? A escolha do próprio modelo e a manutenção também são muito importantes. A seguir, veja comigo. 1. Gama de...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor