Qual é a razão pela qual o sistema de refrigeração industrial não pode ser arrefecido

Let the LNEYA technical engineer explain

the reason for everyone:

The first one: The chiller system fails to

lower the temperature during the first use, or there is a problem with the

installation of the industrial water chiller, cooling tower, circulating water

pump and piping. Need to check carefully according to the installation drawing.

The second one: It may be because the

pipeline is connected to various equipment for a long time, and impurities

accumulate in the water source, which causes the water flow to become smaller.

Therefore, we must clean the pipes between the equipment.

Third: If this problem occurs during the

first use, it may be caused by a mismatch of the chiller and a shipping

problem. Because the industrial water chiller has undergone 100% performance

testing before leaving the factory to ensure the normal operation of the unit.

Finally, if it is a chiller that has been

used for half a year or 1-2 years, it may be caused by a leak of Freon in the

cooling system of the chiller. It is recommended to find out the leaks,

re-soldering, and re-soldering the refrigerant. The heat exchanger of the

industrial water chiller is dirty and needs to be cleaned. Remember to clean it

regularly in the future.

The operation of any industrial water chiller

system is inseparable from the participation of refrigerants. Therefore, the

shortage of refrigerant will also affect the normal operation of industrial

chillers, leading to reduced cooling capacity or even shutdown

of industrial water chillers. This is also the main reason for the shrinking

capacity of industrial chillers.

Recomendações relacionadas

-

Cooling heating temperature control system SUNDI series thermal fluid filling instructions

19201. Refrigeration heating temperature control system SUNDI series equipment before the heat conduction filling, the heat transfer liquid inlet of the heating refrigeration circulator and the heat transfer liquid outlet of the upper end of the react...

Ver detalhes -

Instruções de utilização do frigorífico criogénico industrial

1803Os frigoríficos industriais são uma das máquinas de água fria. São classificados de acordo com o modo de arrefecimento da própria máquina de água fria. Dividem-se em frigoríficos de refrigeração a ar e frigoríficos de refrigeração a água. Caraterísticas estruturais: a ...

Ver detalhes -

Começando com o desenvolvimento de diversificação de produtos de sistemas de refrigeração, aquecimento e controlo de temperatura

1528Wuxi Guanya Refrigeration technology co., ltd foi fundada em 2006. Criou um estúdio de equipamento de refrigeração e aquecimento. Em 2007, lançou o ciclo de refrigeração e aquecimento de primeira geração, registou a marca "LNEYA". Em 2008, lançou...

Ver detalhes -

Falha do compressor do sistema de controlo da refrigeração causada pela pressão do óleo

1607Se não houver pressão de óleo no sistema de controlo de refrigeração, verificar a ligação do sistema de tubagem da bomba de óleo quanto a fugas de óleo ou bloqueios. Se a ligação estiver solta, a junta deve ser apertada. Se estiver bloqueada, a tubagem de óleo deve ser desobstruída...

Ver detalhes

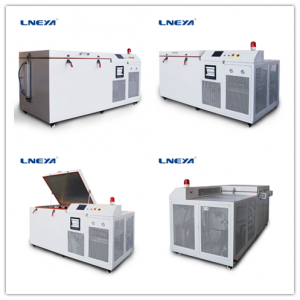

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor