483Meet Your Dream Equipment for Distillate CBD Extraction

If you need equipment to distill CBD, you need to scrutinize your choices, as the equipment can vary in its features and design. When you use equipment that produces a CBD distillate, you want to seek out a system made by a manufacturer that provides proven and reliable products. You should also work with a business that can train you on the use of the equipment you buy.

Probably one of the best examples of distillate extraction equipment today is a short path distillation system – one that is featured by Colorado Extraction Systems (CES). The equipment can produce a high-quality distillate quickly. You can choose from 2 model sizes – 5-liter or 12-liter, with 3 kinds of heads and various styles of receiving cows. This equipment is meant for anyone who wants to produce the highest quality CBD oil.

So how does short path processing work?

The End Product

When you use the equipment for short path processing, you will receive a distillate or a CBD compound in its purest form, which has the following qualities:

· A clear and golden liquid; and

· A compound with no color or taste

That is because the oleoresin in the substance will be stripped to under 25% of its total active compounds. In turn, the liquid loses the original terpenes that produce both a scent and flavor. As a result, the final CBD product can only be described as potent – super-potent. Therefore, the end product can be employed as a precursor for isolation and crystallization.

Check Your Equipment Before Distilling

Before beginning short path distillation, you need to make sure of the following:

· Your vacuum pump should work and operate well. The oil that is produced should always be clear.

· All you glass components should be functional.

· A degassing process and winterization should be performed to prepare the oil for distillation.

Beginning the Process

Once you check on your equipment and perform degassing and winterization, you can start distilling. Remember the following when you begin the short path process:

· Start by placing a stir bar into a boiling flask before you add the material.

· Add the material using a funnel.

· Include a small amount of alcohol in the oil to thin it out. Doing so will make it easier to transfer the oil during distillation.

· When you assemble the glassware, each joint should be properly greased.

· Do not use too much grease, as the vacuum pressure might draw some of the grease into the short path system.

· Ensure a complete seal by spreading grease using a circular motion and rotating the glassware.

· Affix a circulator to the equipment’s condenser and set the temperature to 50 degrees Celsius (122 degrees Fahrenheit).

The circulator should reach the above-listed temperature before you begin using the distillate extraction equipment. By using this type of equipment from a reputable dealer, you can expect impressive results.

Recomendações relacionadas

-

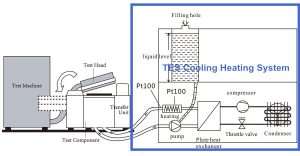

O significado da temperatura nos ensaios de IC

2521Cada circuito integrado (CI) passa por dois tipos de testes antes de poder ser vendido e utilizado para construir um produto: o primeiro é chamado de teste de bolacha; o segundo é chamado de teste final. Com a melhoria da tecnologia de teste elétrico de circuitos integrados...

Ver detalhes -

Characteristics and Advantages of Air Cooled Chillers

16831. Configuration of air-cooled chillerAir cooled chillers can be divided into air-cooled vortex chillers and air-cooled screw chillers according to the type of compressor. The air-cooled vortex chiller is mainly composed of vortex compressor, evap...

Ver detalhes -

Função da bomba de água do refrigerador de água industrial

1806The water pump is one of the important auxiliary components of the refrigeration system of the industrial water chiller. Many industries will use the industrial water chiller, but many people don't know much about the equipment. This time, lneya r...

Ver detalhes -

Suitable Freezer Manufacturer

1328For enterprise users, choosing a suitable freezer manufacturer is very important and must be carefully treated. Wuxi Guanya Refrigeration technology co., Ltd, as a professional freezer manufacturer, is committed to producing all kinds of low tempe...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor