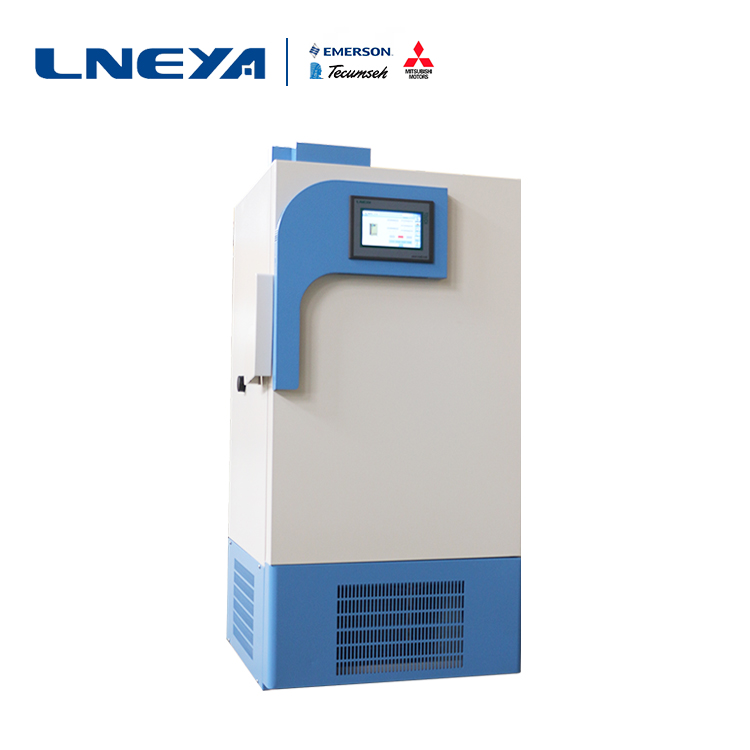

LNEYA ultra-low temperature cold box power supply+electronic control instrument system description

LNEYA ultra-low temperature cold box needs to be tested after a long time of use. What should be paid attention to when the power supply and electronic control instrument system are inspecting?

LNEYA ultra-low temperature cold box power supply and electronic control instrument system inspection, before power-on should check whether the distribution capacity and unit power are consistent, whether the selected cable diameter can withstand the host operating current. Check whether the electrical system is consistent with the unit. The unit is electrically: three-phase five-wire system (three phase lines, one neutral line, one ground line, 380V ± 10%). Check if the power supply line of the compressor is connected tightly. If it is loose, retighten it. The torque at the compressor wiring is 500kg/cm. Due to factors such as long-distance transportation and lifting, the screws may be loose. Failure to do so may result in damage to electrical components (such as air switches, AC contactors, etc.) and compressors in the main control cabinet.

Use a multimeter to carefully inspect all electrical circuits of the LNEYA ultra-low temperature cold box, check that the wiring is properly installed in place; use megaohm measurement to make sure there is no short circuit in the case; check that the ground wire is properly installed in place, and the insulation resistance to ground is greater than 2MΩ; check if the power cable is Meet the capacity requirements. Check if the disconnect switch is installed on the power supply line of the supply unit. All the wiring of the main circuit in the control cabinet and the external wiring of the control circuit can be energized after comprehensive inspection (such as crankcase oil heater, compressor electronic protector, circulating water temperature sensor, target flow switch wiring, pump connection) Control, etc.); Check if the terminal bolts are tightened and there is no looseness.

The performance of the power supply and the electronic control instrument are more important in the operation of the LNEYA ultra-low temperature cold box, so it is necessary to check the recommendations regularly.

Recomendações relacionadas

-

Introdução de frigoríficos para peças metálicas, tais como rolamentos ultracongelados

1359A caixa criogênica de peça de trabalho de congelamento contínuo da LNEYA tem uma taxa de resfriamento rápida e a baixa temperatura pode chegar a -150 ℃. Pode ser usado para montagem a frio de rolamentos e peças mecânicas. O tratamento criogénico pode melhorar as propriedades mecânicas...

Ver detalhes -

Description of the action of the filter in the ultra-low temperature compressor unit

1757In order to stabilize the operation of the ultra-low temperature compressor unit, the performance of the compressor is very important, and in addition to the compressor, the filter is also important. In order to maintain normal operation, it is ne...

Ver detalhes -

A solução para o alarme de falta de refrigerante no termóstato de aquecimento e arrefecimento totalmente fechado

1951O que devo fazer se o termóstato de aquecimento e arrefecimento totalmente fechado emitir um alarme por falta de líquido de refrigeração? Penso que muitos clientes irão deparar-se com este problema quando o utilizarem. De facto, é relativamente simples. Desde que se conheça o princípio ...

Ver detalhes -

Óleo de transferência de calor para sistemas de controlo de temperatura de arrefecimento e aquecimento nos sectores químico e farmacêutico

1746The cooling and heating temperature control system, also known as a high and low temperature circulator or dynamic temperature control system, is a temperature control equipment used in the pharmaceutical and chemical industry to provide cold and ...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor