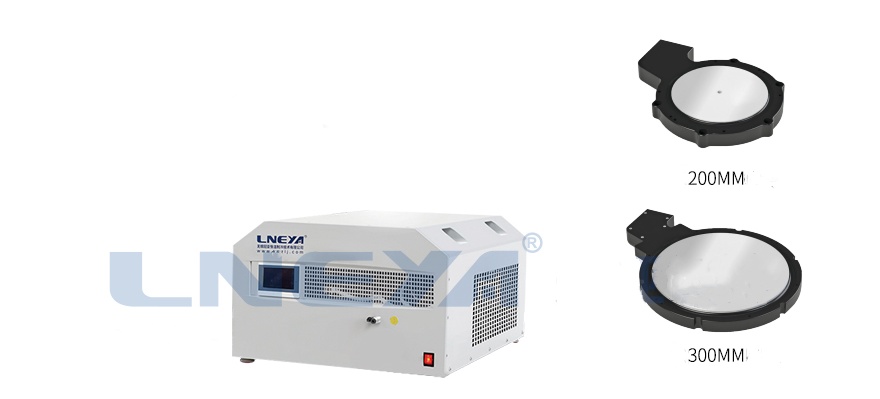

Mandril térmico ou placa térmica/unidade de controlo térmico

MD -75℃~225℃- Precisão da temperatura±0.1℃

- Potência de aquecimento-60°C to +25°C: 2 min 0°C to +25°C: 2 min +25°C to +220°C: 6 min

- Potência de arrefecimento220°C to +25°C: 2 min +25°C to -60°C: 6 min

- Fonte de energia2.8KW

- Forma planaRedondo/quadrado

Mandril de controlo de mudança rápida de temperatura

-75℃ to 225°C

|

Modelo |

MD-708 |

MD-712 |

MDL-708 |

|

Temp. Gama |

-75℃~225℃ |

-75℃~225℃ |

-75℃~225℃ |

|

Precisão do controle de temperatura |

±0.1℃ |

±0.1℃ |

±0.1℃ |

|

uniformidade da temperatura |

±1℃ |

±1℃ |

±1℃ |

|

Planicidade |

±50um |

±50um |

±50um |

|

Tamanho do tablet |

Disco de 200 mm de diâmetro |

Disco com 300 mm de diâmetro |

150mm*200mm |

|

Cabo do anfitrião e da placa |

2,5 m (outros comprimentos podem ser personalizados) |

||

|

Tratamento de superfícies planas |

Níquel electrodepositado (revestimento dourado opcional) |

||

|

Aquecer |

-60°C to +25°C: 2 min 0°C to +25°C: 2 min +25°C to +220°C: 6 min |

||

|

Arrefecer |

220°C to +25°C: 2 min +25°C to -60°C: 6 min |

||

|

Sistema de controle |

Controlador PLC, algoritmo difuso PID de alimentação de aquecimento, válvula de expansão eletrónica de arrefecimento, controlo de ajustamento PID da capacidade de arrefecimento |

||

|

Visualização e registo |

Ecrã tátil a cores de 7 polegadas, curva de temperatura de registo |

||

|

Comunicação |

Interface Ethernet Protocolo TCP/IP |

||

|

Compressores de refrigeração |

Taikang |

||

|

Fonte de alimentação |

220V 50/60HZ 2,8KW |

220V 50/60HZ 4,5KW |

220V 50/60HZ 2,8KW |

|

Tamanho do hospedeiro mm |

550×650×370 |

550×650×370 |

550×650×370 |

Descrição do produto

A maior inovação da MD em matéria de ensaios térmicos é a série de mandris controlados termicamente, que são principalmente utilizados para ensaios de desempenho, modelação, desenvolvimento de processos, defeitos de conceção ou análise de falhas de CI de bolachas semicondutoras. Pode efetuar mudanças rápidas de temperatura e controlar a temperatura com precisão. O sistema tem o seu próprio frigorífico, o que evita o consumo de nitrogénio líquido, dióxido de carbono, etc., e cada sistema inclui um mandril e uma unidade de controlo a frio e a quente.

O interior da placa adopta o método de evaporação direta do refrigerante, o que melhora consideravelmente a eficiência da troca de calor e a potência de troca de calor por unidade de área da placa, em comparação com o método de arrefecimento por líquido.

Rapid cooling/heating rates up to 25°C/min

Refrigerador incorporado para evitar o consumo de nitrogénio líquido, dióxido de carbono, etc. Automação programável, estabilidade de temperatura +/-0.1℃

O controlador fornece um ecrã tátil e uma interface remota para controlar e monitorizar com precisão a temperatura do equipamento

Display test status – real-time data

A série Thermal Chuck MD oferece uma plataforma de trabalho de superfície plana aberta, subida e descida rápidas da temperatura e controlo constante da temperatura, que pode ser utilizada para testar dispositivos RF e dispositivos de potência de alta densidade (IGBTS E MOSFETS), e também pode ser utilizada para o arrefecimento rápido de painéis planos de laboratório (plasma, produtos biológicos, baterias), etc.

Correio eletrónico: sales@cnzlj.com

WhatsApp: 086 13912479193

Recomendações relacionadas

-

A diferença entre a tecnologia de arrefecimento líquido por contacto direto e a tecnologia de arrefecimento líquido por placa fria

2004A tecnologia de arrefecimento por líquido de placa fria é um método de implementação em que o calor dos componentes de aquecimento é indiretamente transferido para o líquido de arrefecimento contido na tubagem de circulação através da placa fria, e o calor é...

Ver detalhes -

Série de aquecimento com arrefecimento direto KRY

3736Condições de teste nominais: temperatura do bulbo seco 20 ℃; temperatura do bulbo úmido 16 ℃. Temperatura da água de entrada 20 ℃; temperatura da água de saída 25 ℃. Os dados nesta tabela são apenas para referência. Por favor, consulte o nome da unidade ...

Ver detalhes -

YQH 0℃~-75℃

2999Adequado para a recuperação de vários gases VOCs voláteis; Arrefecimento rápido, alta eficiência, atendendo a diferentes requisitos de temperatura de condensação, a baixa temperatura pode chegar a -75 ° C. Ele vem principalmente da limpeza, cola ...

Ver detalhes -

Série LQ

4247É utilizado para arrefecer o gás (não corrosivo) ou recuperá-lo como gás não corrosivo por condensação e liquefação. Resistência à pressão do sistema de troca de calor a gás: 25bar; A faixa de temperatura é de - 40 ℃ ~ - 75 ℃, que pode atender a diferentes...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor

Submeter para consulta

Responder-lhe-emos no prazo de 24 horas