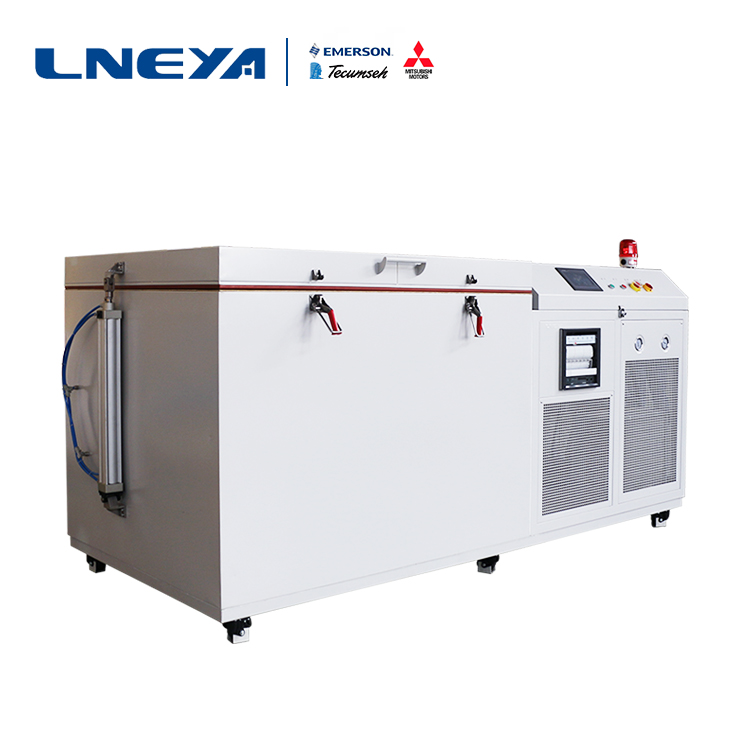

Como evitar que a pressão de congelação da caixa de congelação rápida de rolamentos seja demasiado baixa?

In the refrigeration system of the bearing blast chiller, if the condenser installation is not in the enclosed space, the system’s exhaust pressure (condensation pressure) tends to be lower in winter (or low temperature), which is often more common in the north. For bearing blasters, this is also the case for other equipment.

The low condensing pressure of the bearing quick freezing box will make the expansion valve unable to obtain sufficient pressure drop at both ends, and it is difficult to supply the appropriate refrigerant to the evaporator. On the one hand, the cooling capacity of the refrigeration system will not meet the requirements, and the system will also be made. Frequent low-voltage alarms and other faults.

To this end, we can deal with the method of exhaust pressure controller. When the intermittent operation of the fan is simple and easy to use, and the technology is mature, the controller used is a pressure controller. This pressure controller can control the intermittent start and stop of the fan. When the pressure is too low, turn off the fan. When the pressure is too high, turn on the fan. Generally, on a small-capacity unit, use two or more fans, one of which is normally open, and the other fans are pressure controlled. The controller controls the start or stop of the fan by the level of the condensing pressure.

It is also possible to use a pneumatic control device to utilize a high-pressure refrigerant-driven piston-type damper. This control device can operate as a stable exhaust pressure as the fan speed controller; the main reason is that the inlet pressure of the expansion valve does not resemble a fan. Intermittent operation produces large fluctuations, and the louver device can be installed either at the air inlet or at the air outlet.

In addition, the condenser overflow device can also be used to increase the condensing pressure of the system by using excess refrigerant, and the condenser overflow device is used for warming or low temperature environment, and the large flow refrigerant is taken from the liquid storage device. It is sent to the condenser, and the excess refrigerant is used to increase the condensing pressure of the system, thereby avoiding the failure of the condensing pressure being too low at low temperatures.

LNEYA’s methods to prevent the bearing chiller from condensing too low pressure are still relatively high, and users can try it according to their own needs.

Recomendações relacionadas

-

Método de controlo da paragem do refrigerador arrefecido a água de uma única caldeira de reação

1280The reaction kettle water cooled chiller has a wide range of accessories and equipment. In actual use, it needs to be provided with regular rest time. In order to maintain the stable performance of the refrigerator during long-term operation, it i...

Ver pormenores -

Importância dos fluidos frigorigéneos nos sistemas de ensaio de baterias de veículos de energia nova

1243Se o caudal do refrigerante no sistema de teste da bateria do veículo de energia nova for extremamente pequeno, o refrigerante começará a expandir-se a partir do primeiro espaço expansível na extremidade traseira da válvula de estrangulamento. A maior parte da expansão da extremidade traseira da...

Ver pormenores -

Como é que um fabricante de chillers industriais deve escolher

7462. Tente selecionar fabricantes de chillers industriais de marcas bem conhecidas com experiência de trabalho técnico profissional. 3. se houver visitas e inspeções, devemos dar grande importância aos grandes aspectos e prestar mais atenção ao pequeno ponto-chave...

Ver pormenores -

Routine maintenance of tcu multi-reactor temperature control equipment

930TCU multi-reactor temperature control equipment is widely used in research departments such as petroleum, chemical, electronic instruments, physics, chemistry, bioengineering, physical property testing and chemical analysis, colleges and universi...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor