Princípio de refrigeração do sistema de refrigeração de glicol LNEYA

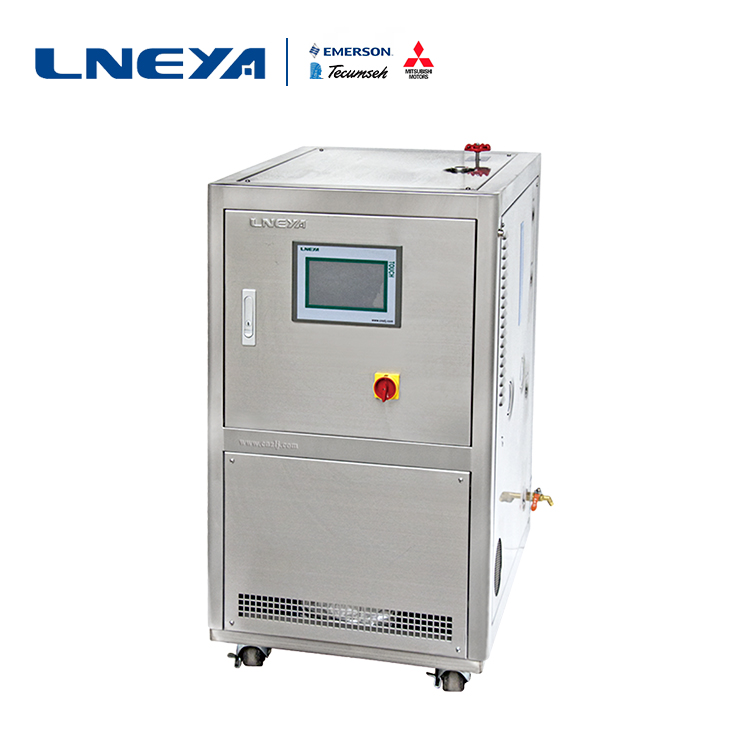

Glycol Chiller System SUNDI -10℃ ~ 200℃, as we can tell from its name, it is to use Glycol as the refrigeration agent for the chiller.

In the all air environment, because of the low temperature in the outdoors, it is impossible to use a cooling tower to supply the inner area directly with the cold air-conditioner. In addition, the cold air in the outdoors could be used directly as refrigerator source,with glycol as refrigerant, it can introduce the natural cold air into the inner area and supply cold air-conditioner. If we need to heat the outer area and provide cooling for the inner area, we can turn off the chiller and still use the boiler or the urban hot water as the heat source to heat the outer area.

Install plate heat exchanger in the outdoor, and the outdoor cold air is introduced into the plate heat exchanger by the fan. The glycol solution and the outdoor cold air are exchanged in the plate heat exchanger. The cooled glycol solution enters into the air conditioners in the inner area and exchange with mixed air. Then the mixed air enters into the inner room with lower temperature and supply cooling. The temperature of glycol solution rise up, it comes back to the plant heat exchanger in the outdoor again, exchange heat with the cold air in the outdoor and continue this cycling after the temperature is lowered. This way of heat exchange is usually used in the heat recycling system.

It is a very energy-saving way that use glycol as a refrigerant to introduce the cold air in the outdoors to supply cooling for the inner area. All we need to do is to install a plant heat exchanger in the outdoor when it works, the cold water equipment closed, opening the fan and the air conditioners can bring cooling for the inner area. In this way, we can save energy and reduce the cost.

Recomendações relacionadas

-

Commissioning of circulating water chiller equipment in the chemical industry

1014After completing the installation of circulating water chillers in the chemical industry, certain debugging needs to be carried out in the early stage of operation. Only through careful debugging can we find out whether there are hidden troubles i...

Ver pormenores -

What is the reason why the industrial chiller system cannot be cooled

1237Let the LNEYA technical engineer explainthe reason for everyone: The first one: The chiller system fails tolower the temperature during the first use, or there is a problem with theinstallation of the industrial water chiller, cooling tower, ...

Ver pormenores -

A introdução dos refrigeradores de recirculação de temperatura ultra baixa

1124Os desempenhos dos chillers de recirculação de temperatura ultra baixa são diferentes devido aos seus diferentes compressores. Em comparação com o compressor de pistão, a estrutura do compressor de parafuso tende a ser mais precisa, por isso, quando os utilizadores precisam de selecionar...

Ver pormenores -

Closed laboratory circulator enameled mixing tanks refrigeration and heating system

839Closed laboratory enameled mixing tanks refrigeration and heating system

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor