Como evitar o funcionamento incorreto do circulador de aquecimento e arrefecimento?

When the user runs the heating and cooling circulator, the operation needs to follow the instructions. Then, how to avoid unsuitable operation?

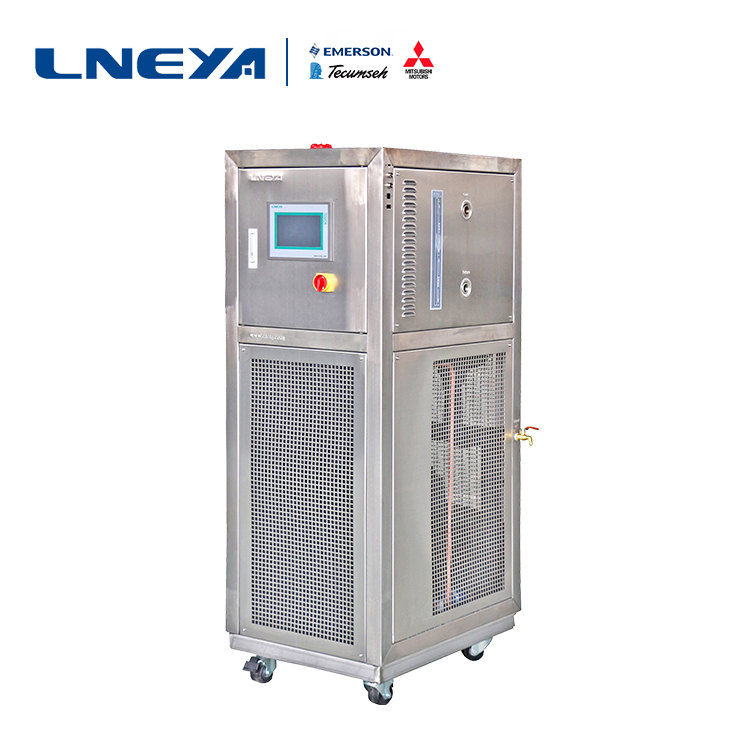

LNEYA heating and cooling circulator has multi-function alarm system and safety function. It uses plate heat exchanger and pipeline heater to increase heating and cooling rate. Large-screen touch screen graphic display, heating and cooling machine uses magnetic drive pump, no shaft seal leakage problem. Fully enclosed system, extending the life of the thermal fluid, a very wide temperature range, without the need to change the liquid medium.

Before the heating and cooling circulator is turned on, the inlet valve of the condenser on the unit that does not need to be opened is turned off to cause drowning, and a part of the cooling back water flows away from the condenser of the starting group, thereby reducing the cooling water in the condenser of the running unit. The flow rate causes the condensing pressure to rise. The operating current of the main unit increases. The cooling capacity of the unit is reduced, and the unit will be shut down seriously. It wastes electricity and reduces the cooling effect, and it is also easy to damage the equipment.

Due to the previous misoperation, the condensing pressure of the main engine and the temperature of the cooling water effluent rise, causing misjudgment to the operator. It is mistaken that the cooling water is not enough to open the condenser inlet valve and the cooling water pump outlet valve, and some also increase the cooling tower fan, resulting in increased power consumption of the pump and cooling tower fan. In addition, some users blindly added a cooling water pump. Although the addition of the cooling water pump can indeed reduce the cooling water temperature and the condensing pressure, after all, the power of one pump is wasted, so it is wrong.

The correct operation method of the heating and cooling circulator is that the unit condenser inlet valve is not required to be closed before starting to prevent drowning. Opening the heating and cooling unit will run the inlet and outlet valves on the unit condenser (the general outlet valve is normally open, the inlet valve is opened and closed as needed, and the condenser and evaporator are the same) to open the corresponding cooling water pump. Adjust the inlet and outlet pressure of the condenser to about 68.6 kPa (0.7 kg/cm). If the condenser inlet and outlet pressure gauges are swung too far, the cooling water system has air. The air should be vented until the pressure gauge indicates normal and continue to the next step.

During the use, do not handle all kinds of faults yourself, and avoid secondary damage caused by improper handling.

Recomendações relacionadas

-

A diferença entre unidades de refrigeração 15P arrefecidas a ar e arrefecidas a água

1173Como as condições de procura são diferentes, quando a unidade de refrigeração 15P selecionada é arrefecida a ar e arrefecida a água, qual é a diferença? A unidade de refrigeração 15P arrefecida a ar contém um tanque de água com isolamento térmico e uma bomba de água no seu corpo, ...

Ver pormenores -

Como resolver o problema da capacidade de refrigeração insuficiente do sistema de ciclo de refrigeração de semicondutores?

1275O sistema de ciclo de arrefecimento de semicondutores é um dispositivo para arrefecer a parte de aquecimento dos semicondutores. A LushiA recorda que, se a capacidade de arrefecimento for insuficiente durante o funcionamento, é necessário verificar a tempo se algo correu mal. W...

Ver pormenores -

Descrição do erro de seleção do equipamento de teste do módulo de bateria

1005Muitas empresas de módulos de bateria têm alguns mal-entendidos sobre o equipamento de teste de módulo de bateria da LNEYA. Existem alguns erros na seleção do modelo de equipamento de teste do módulo de bateria, portanto, tente selecionar o equipamento de teste do módulo de bateria. Evite alguns mi...

Ver pormenores -

Refrigeradores de canal duplo para a indústria de fabrico de semicondutores

949Os refrigeradores de canal duplo são utilizados numa variedade de processos na indústria de fabrico de semicondutores. O principal objetivo é fornecer um controlo preciso da temperatura para garantir que o equipamento no processo de fabrico de semicondutores funcione...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor