LNEYA tratamento do choro super profundo com bom senso

For ultra-deep cold processing equipment, failure to pay attention to the use of the equipment may cause equipment failure.

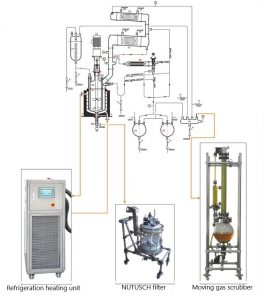

Before using the water-cooled ultra-cry cryogenic treatment, it should be checked whether all the valves between the equipments are open, whether all the water tanks are filled with water, whether the fans are reversed, and whether the circulating water pump is running in the correct direction. Open the super deep crying treatment main power supply (the standard power supply is 3-phase five-wire system 380V 50HZ), specifically the water-cooled ultra-deep cold treatment front nameplate. Wuxi Guanya LNEYA reminds everyone that the power supply for ultra-deep cooling must be stable to avoid burning the unit or compressor and pump motor.

First open the ultra-deep cooling treatment cooling switch, then turn on the chilled water pump switch. Since the compressor has a delayed start function, the compressor will automatically run after the delay. At this time, pay close attention to the front control panel to observe the temperature change, as appropriate according to the cooling demand. Perform temperature adjustment. Water-cooled ultra-cry cryogenic treatment During normal operation, the unit operation data should be recorded periodically to facilitate the identification of problems based on data as soon as the unit fails. The ultra-cryogenic treatment itself is provided with multiple protection devices. Once there is a fault, it will start to protect and automatically stop. After the fault is removed, press the reset to operate normally.

When the super-cryogenic treatment is not used, the unit, water pump, insulated water tank and water in the pipeline should be drained, and the equipment should be covered and protected to avoid dust and other debris. Regarding the maintenance of ultra-deep cold treatment, this cannot be ignored. It is necessary to clean the condenser and evaporator after running for half a year. It is recommended to carry out maintenance of the whole machine after one year of operation, and keep it clean and clean regularly.

The instruction manual of the ultra-cryogenic treatment equipment and regular inspection and maintenance are all parts that the user needs to know in order to make the equipment run more efficiently.

Recomendações relacionadas

-

Types of Environmental Tests

1766The environmental chamber is one of the many types of experiments used in scientific research, product development, production and evaluation. The fundamental difference between environmental tests and other tests is that there are specific requir...

Ver detalhes -

Como resolver o problema da falha da bomba de circulação da bomba de refrigeração?

1712Os dispositivos de aquecimento por refrigeração são necessários em muitas aplicações químicas, farmacêuticas e laboratoriais. Então, como resolver a falha do dispositivo de aquecimento de refrigeração também está preocupado com a forma de resolvê-lo? 1. Falha da bomba de circulação A bomba de circulação...

Ver detalhes -

Explicação pormenorizada da atenção a dar à depuração do sistema de arrefecimento de circulação fechada

1757A preparação do sistema de arrefecimento de circulação fechada antes da colocação em funcionamento é uma parte importante do processo de depuração, que pode afetar o progresso de todo o processo de depuração. Geralmente, deve ser dada atenção à deteção de fugas...

Ver detalhes -

Ambiente de utilização do refrigerador do equipamento de controlo da temperatura de deposição de película fina em bolacha

1631Ambiente de utilização para o refrigerador de arrefecimento de deposição de película fina de bolacha

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor