High and low temperature circulation tank daily use instructions

During the operation of the high and low temperature circulation tank, some phenomena generated by the LNEYA protection device need to be observed. If some improper sounds and unexpected situations occur, we need to solve it in time.

The high and low temperature circulation tank is not connected to the power switch, forget to turn on the leakage circuit breaker, and turn the leakage circuit breaker to ON. There is no input from the power supply: the fuse is burnt. In order to ensure the safe and reliable operation of the refrigeration system and prolong the service life of the compressor, please pay attention to daily maintenance. Before starting the compressor, pay attention to whether the valve to be opened in the exhaust cut-off valve and its system is in the correct position, and check whether the power supply voltage and ambient temperature are within the specified range. During the operation of the compressor, the suction and exhaust pressure of the compressor should not exceed the range of use, and the operation sound of the compressor should be heard. Except that the intake valve and exhaust valve have clear pouring sound, other parts should not be knocked. When the sound is heard, it is found that the leak should be repaired in time. When the compressor is stopped for a long time, the refrigerant should be recycled to the reservoir and the exhaust shutoff valve should be closed.

The high and low temperature circulation tank adopts a fully closed pipeline design and adopts a high efficiency plate heat exchanger. It is applied to the temperature rise and temperature control of the glass reactor, metal reaction kettle and bioreactor, especially suitable for heat and release during the reaction process. Thermal process control. The high and low temperature circulation tank is applied to the temperature rise and temperature control of the glass reactor, the metal reaction kettle and the bioreactor, and is particularly suitable for controlling the heat demand and the heat release process during the reaction process.

Every accessory in the high and low temperature circulation tank is very important. Once the fault occurs, it needs to be solved in time. In the process of running, pay more attention to the maintenance in time to ensure the efficient operation of the accessories.

Recomendações relacionadas

-

Manutenção e conservação do refrigerador de simulação da temperatura de ensaio da bateria

1400O chiller de simulação de temperatura de teste da bateria é cada vez mais utilizado nas empresas, mas a manutenção e a manutenção subsequentes também são mais importantes. Aqui está uma breve introdução a alguns métodos de manutenção e manutenção. 1....

Ver detalhes -

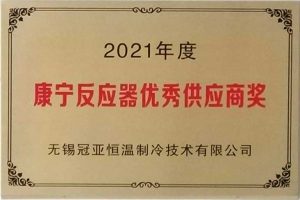

Ganhou o prémio "Excelente fornecedor de equipamento de controlo da temperatura de reactores em 2021"

4621LNEYA was awarded the "2021 Excellent Supplier of Reactor Technology" by Corning, a Fortune 500 company in the United States. Since 2015, LNEYA has won this award for 7 consecutive years. Therefore, in the reactor manufacturing industry, we have ...

Ver detalhes -

Aplicação de TCU em sistemas de refrigeração e de circulação de calor

1842No processo de síntese farmacêutica e operação de química fina, encontramos frequentemente reacções exotérmicas fortes, como a reação de oxidação e a neutralização ácido-base. No caso destas reacções exotérmicas fortes, se o controlo for inadequado ou a...

Ver detalhes -

High-low temperature control system with different configurations of high-pressure reactors

1361Different configurations of high pressure reactors, the quality of products brought by different manufacturers is not the same, but the points of attention are the same, you need to pay attention to it. 1. To be used at the designated location and...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor