Quais são as funções da câmara de ensaio de envelhecimento a alta e baixa temperatura para a produção de pastilhas?

Atualmente, a indústria de produção de bolachas com chip está a enfrentar desafios e mudanças sem precedentes. Para além da tecnologia, a produção sempre foi uma preocupação na indústria. Todos nós sabemos que o nascimento de um chip requer muitos processos, e um bom chip...

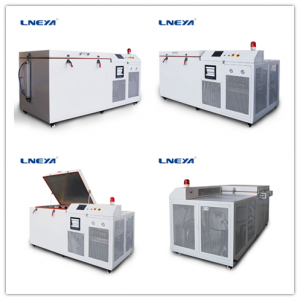

The test of the chip industry is related to the quality of each chip version, so the chip high and low temperature aging test box is very necessary in the development of the chip industry.

The complexity of chips is getting higher and higher. In order to ensure that there are no problems with the chips that leave the factory, it is necessary to test before leaving the factory to ensure functional integrity. As the chip is a mass-produced thing, large-scale automated testing is Weiyi’s solution. It is impossible to accomplish such a task by manual or bench test. The chip high and low temperature aging test box is actually a relatively large category, which is generally divided into wafer test and final test from the test objects. The objects are chips that have not been packaged and chips that have been packaged. Why is it divided into two paragraphs? Simply put, because packaging also has a cost, in order to save costs as much as possible, a part of the test may be performed before the chip is packaged to exclude some broken chips. In order to ensure that the chips shipped from the factory are all right, the final test, that is, the FT test, is an interception, and it is also a necessary link.

Generally speaking, the chip high and low temperature aging test box includes pin connectivity test, leakage current test, some DC (direct current) test, functional test (functional test), Trim test, and some other tests according to the chip type. For example, AD/DA will have some special test types. The purpose of chip testing is to save costs as much as possible while finding the correct chips. Therefore, defects that are easy to detect or more common will be tested first. Generally speaking, the first thing we will do is connectivity test, which we call continuity test. This is to check whether the connectivity of each pin is normal.

The chip high and low temperature aging test box mainly saves costs for the chip industry, and can give priority to selecting good quality chips.

Recomendações relacionadas

-

Porque é que as fábricas mecânicas necessitam de refrigeradores?

1271Há muitas razões pelas quais as fábricas mecânicas precisam de refrigeradores, e os refrigeradores desempenham um papel muito importante no processo de processamento mecânico, o que pode melhorar a eficiência da produção, garantir o funcionamento estável do equipamento e estender o equipamento ...

Ver detalhes -

12hp freezer heat transfer oil selection instructions

1764When choosing a 12hp freezer, users need to pay attention to the choice of heat transfer oil. For LNEYA, suitable heat transfer oil is very important. What should you pay attention to when choosing heat transfer oil? The 12hp freezer adopts a full...

Ver detalhes -

Como utilizar o equipamento de circulação a alta e baixa temperatura na extração e separação?

1291With the continuous development of science and technology, high and low temperature cycle industrial temperature control equipment plays an important role in many fields, especially in the field of extraction and separation. This article wil...

Ver detalhes -

How to solve the phenomenon of ultra-low temperature freezer card cylinder?

2173If the ultra-low temperature freezer room fails during operation, it needs to be solved in time. If it is similar to the related phenomenon, it may be that the frozen oil does not come up, and the operator needs to solve it in time. Ultra-low temp...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor