Reactor Thermal Control Unit and Solutions for Chemicals

Temperature control is a process in which the temperature of a substance or a change in temperature is measured or otherwise detected, and the transfer of thermal energy into or out of the space or substance is adjusted to achieve the desired temperature.

When dealing with pharmaceutical production, maintaining accurate temperature control is critical. Starting with research throughout production, precise temperature control is required at every stage of the process. We fully understand the importance of process cooling, and simple temperature fluctuations (positive and negative) can ruin research or production.

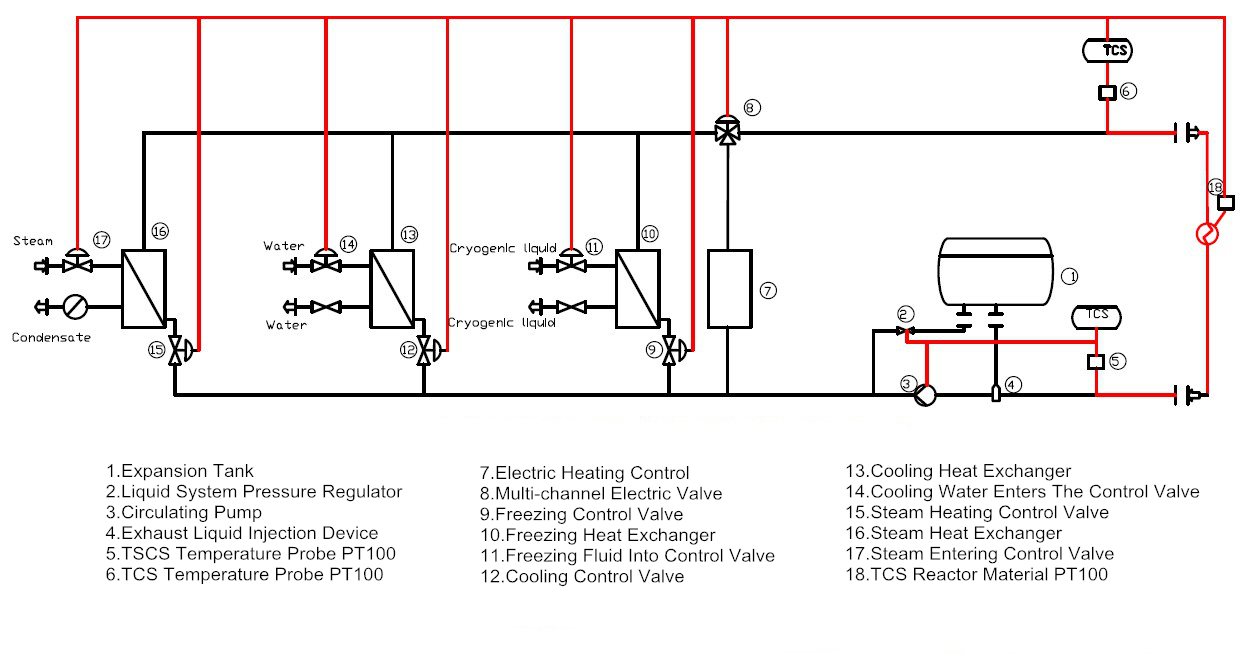

Our TCU can meet all your heating, cooling and temperature control needs for your chemical or pharmaceutical reactor. The LNEYA-TCU temperature control system can utilize existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration to achieve dynamic temperature control of the equipment temperature in a single fluid system or a secondary circuit. This only completes the flow of a heat transfer liquid into the jacket of the reaction vessel (rather than directly into the steam, cooling water or cryogenic liquid), and the temperature of the entire reaction process is controlled by calculation.

From -120°C for cryogenic pharmaceutical applications to 300°C for chemical applications, the maximum temperature can be set according to the supplier’s heating or cooling source. The maximum temperature range can be set using a glycol water formula. Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), and our own model-free self-building algorithm and general anti-lag cascade algorithm, the problem of large drug delays is solved. Chemical temperature control . Our SR series and ZLF series are completely suitable for low temperature reaction, synthesis, separation process, pilot plant, reactor system, autoclave, combinatorial chemistry, etc.

This will increase product profitability and reactor utilization, and reduce energy and plant operating costs. Our TCU is fully automated and easy to operate. The temperature control accuracy of the product is ± 0.5 ° C, and the cooling power can be provided from 0.5 kW to 1200 kW.

The picture below shows the TCU thermal control unit customized by domestic customers

Recomendações relacionadas

-

Atenção à colocação do sistema de aquecimento e refrigeração de nível industrial

1893Sistema de aquecimento e refrigeração de nível industrial Antes de ligar a corrente eléctrica, verifique se a tensão especificada na placa de identificação é a mesma que a tensão doméstica. O mesmo pode ser usado para organizar linhas eléctricas separadas e tomadas especiais para o ...

Ver detalhes -

Instruções de preparação da série TES-5 dedicada ao teste de chips

1586A série TES-5 para teste de chips é utilizada para testes de componentes electrónicos. A forma de detetar com precisão o chip é muito importante. Então, quanto é que sabe sobre a preparação do teste para a série TES-5 para teste de chips? Antes de iniciar o teste da série TES-5...

Ver detalhes -

A que é que devo prestar atenção quando o preço das unidades de refrigeração de 5p é demasiado baixo?

1590As unidades de refrigeração 5p são equipamentos de refrigeração comummente utilizados em várias indústrias. Os utilizadores terão definitivamente em conta o fator preço quando compram. No entanto, Wuxi Guanya (LNEYA) lembra a todos que existem certas diferenças entre os...

Ver detalhes -

What are the effects of the oil separator on the equipment analyzed by the chiller manufacturer

1360Oil separators use more accessories in thechiller refrigeration system. So as users, we need to understand where the mainimpact is in order to better use the equipment.In the configuration of the chiller, theposition of the oil separator is aft...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor