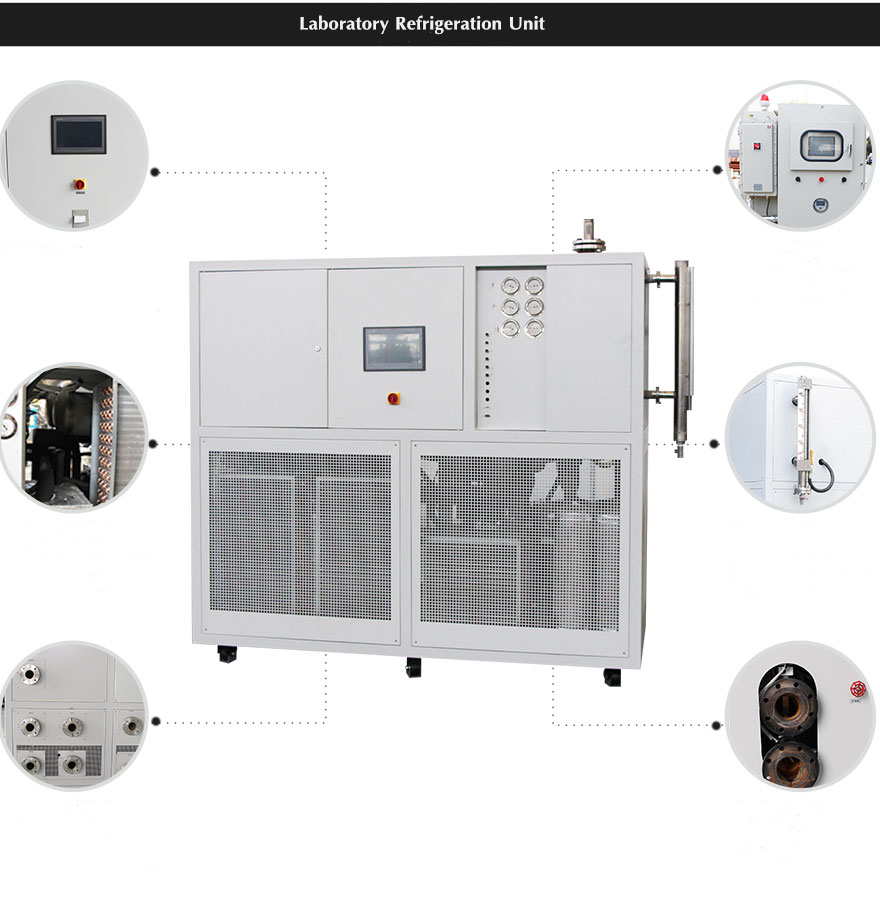

Pontos de manutenção de rotina de unidades especiais de refrigeração para instrumentos de laboratório

Industrial refrigeration units dedicated to laboratory instruments are used more in the pharmaceutical and chemical industries, and care must be taken when using them.

The daily maintenance of the industrial refrigeration unit dedicated to experimental instruments is mainly reflected in the following aspects:

1. Condenser

The high-temperature and high-pressure Freon of the refrigeration system of the industrial refrigeration unit dedicated to the experimental instrument comes out of the compressor and enters the condenser, releasing a large amount of heat to the cooling medium and being liquefied by the cooling.

If the industrial refrigeration unit dedicated for laboratory instruments has been used for more than half a year, or the high and low pressure engines frequently fail, or the cooling capacity is reduced, please arrange a technician to clean the condenser. The fin condenser is generally cleaned with a high-pressure water gun. Be careful not to clean it sideways, which can easily cause the fin to fall over. Shell-and-tube condensers are generally immersed and circulated with descaling chemicals, and then the end cover is opened, and the pipes are cleaned one by one with a gun gun. Cleaning the condenser can significantly improve the refrigeration efficiency of the industrial refrigeration unit dedicated to laboratory instruments.

2. Compressor

Every time the compressor operating time of the industrial refrigeration unit dedicated to the experimental instrument exceeds one thousand hours, all details of the compression equipment should be checked. For example: whether the lubricating oil is normal; whether the running current of the compressor is normal; whether there is any abnormality when the compressor is running. Of course, the current refrigeration technology is quite mature, there are many sensors and protectors. When the unit alarms the fault, it should be repaired according to the fault location. When the compressor makes abnormal noise when it is running, it should be shut down for maintenance, mostly due to insufficient lubricant.

3. Refrigerant

The industrial refrigeration unit dedicated to experimental instruments is an indispensable equipment for industrial production now, and each unit is inseparable from the participation of refrigerant, so the lack of refrigerant will affect the normal operation of the machine and will appear The cooling capacity of the industrial refrigeration unit dedicated to the experimental instrument is insufficient, or the cooling temperature is very slow.

Routine maintenance cannot be ignored. Effective maintenance can keep the industrial refrigeration unit dedicated to laboratory instruments in an effective state of operation.

Recomendações relacionadas

-

Vários aspectos de atenção do congelador de temperatura ultra baixa

1777O desempenho do congelador de temperatura ultra baixa será reduzido naturalmente devido à aplicação de longo período em todos os campos. Assim, Guanya Refrigeration Technology Co., Ltd, líder em fabricantes de congeladores de ultra baixa temperatura tem que lembrar a todos os utilizadores...

Ver detalhes -

Purchasing a special chiller for etching machine and precautions for operation

1722The special chiller for etching machine is used for testing of components, chips, etc. These industries are more supporting use, so what aspects should be paid attention to when choosing the chiller for etching machine drilling? What should I pay ...

Ver detalhes -

Partilha de conhecimentos sobre a seleção e manutenção de refrigeradores

1725Os chillers podem ser usados em muitas indústrias, mas quem é o melhor fabricante de chillers de baixa temperatura nos principais fabricantes de chillers? A escolha do próprio modelo e a manutenção também são muito importantes. A seguir, veja comigo. 1. Gama de...

Ver detalhes -

Descrição ambiental do condensador de um grande congelador industrial

1712No processamento industrial de frio, os grandes congeladores industriais são um dos equipamentos mais utilizados. Entre eles, o condensador é um dos principais componentes, e seu desempenho é muito importante. Por isso, na hora de escolher, todos precisam entender o que é o condensador...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor