O que fazer quando o alarme de alta pressão do chiller?

People must pay attention to the maintenance of large-scale temperature control equipment such as industrial water chiller. Sometimes it is normal to encounter high-pressure alarm. We must first find out the causes of high-pressure of the industrial water chiller, and then we can solve the problem according to the remedy.

The causes of high pressure fault of industrial water chiller are as follows:

(1) The cooling water flow is insufficient to reach the rated water flow. The main performance is that the pressure difference between the inlet and outlet water of the unit becomes smaller (compared with the pressure difference at the beginning of system operation), and the temperature difference becomes larger. The reason for insufficient water flow is the lack of water or air in the system. The solution is to install an exhaust valve at the height of the pipeline for exhaust. If the pipeline filter is blocked and the water permeability is limited, appropriate filter shall be selected and the filter screen shall be cleaned regularly; The water pump is small and does not match the system.

(2) The cooling water temperature is too high and the condensation effect is not good. The rated working condition of cooling water required by the chiller is 30 ~ 35 ℃, high water temperature and poor heat dissipation effect will inevitably lead to high condensation pressure, which often occurs in high temperature season. The reason for high water temperature may be: cooling tower failure, such as the fan is not turned on or even reversed, and the water distributor does not turn, which shows that the cooling water temperature is very high and rises rapidly. The external temperature is high, the waterway is short and the amount of recyclable water is small. In this case, the cooling water temperature is generally maintained at a high level, which can be solved by increasing the water storage tank.

If you have seen the above two solutions and have other problems, you can contact us sales@lneya.com 。 We lneya have professional technical engineers who can help you solve your questions.

Recomendações relacionadas

-

Refrigeração do tanque de reação em vidro

1310Os refrigeradores são utilizados para arrefecer tanques de reação em vidro. Trata-se de uma prática comum, especialmente em situações em que é necessário um controlo preciso da temperatura durante as reacções químicas. Os refrigeradores podem proporcionar efeitos de arrefecimento estáveis para garantir que a tempera...

Ver detalhes -

High-low temperature control system with different configurations of high-pressure reactors

1359Different configurations of high pressure reactors, the quality of products brought by different manufacturers is not the same, but the points of attention are the same, you need to pay attention to it. 1. To be used at the designated location and...

Ver detalhes -

É correto prolongar a duração da bateria baixando a temperatura ambiente?

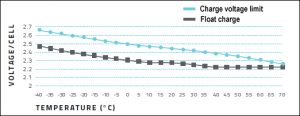

1539The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Ver detalhes -

Como remover a casca do refrigerador de temperatura ultrabaixa e a escala do condensador do tubo?

1752Low-temperature refrigerator ultra-low temperature condenser scale removal In general, we have three methods, namely mechanical descaling, chemical pickling and descaling, and electronic magnetic water separator descaling. Low-temperature refriger...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor