How to deal with organic waste gas treatment refrigerant leakage?

In the process of organic waste gas treatment, if it is found that the refrigerant leaks, it is recommended to treat it in time. LNEYA organic waste gas treatment professional manufacturer then analyzes the knowledge of organic waste gas treatment refrigerant leakage.

Organic waste gas treatment VOCS gas single material or multi-material condensation recovery, the main treatment gases are: hydrocarbons such as gasoline, crude oil, fuel oil, kerosene, diesel, heavy oil, mixed hydrocarbons; aromatics: benzene, toluene, xylene, Styrene, naphtha, etc.; alcohols, ethers, ketones, esters, etc., in the event of a situation, we must now fill the leak or treatment of the refrigerant leakage, then replace the desiccant, re-vacuum treatment, Fill the appropriate refrigerant. When you find that the leaking refrigerant is partially immersed in water, stop the chiller and quickly remove the water from the tank to prevent the compressor from drawing water into the system for more serious damage.

So, what should be done if the organic waste gas treatment refrigerant is found to be insufficient? Organic waste gas treatment failure phenomenon: the whole vehicle refrigeration effect is poor, the air outlet air is only cool, and the manifold pressure gauge check finds that the high pressure is cut and the low pressure side pressure is low (when the compressor speed is 2000/mim, the ambient temperature is about 35C). The low pressure gauge index is lower than 1kg/CM square, the high pressure gauge index is lower than 10kg/CM square, and the bubble flow is visible from the sight glass.

This may be due to a refrigerant leak point in the refrigeration system, resulting in insufficient refrigerant. Treatment method Use an electronic leak detector to detect the leak point and carry out the replacement or replacement of parts. If the parts are not replaced, only the appropriate amount of refrigerant can be replenished; if the parts are replaced, the appropriate amount of refrigerating oil should be added as required, and the refrigerant should be added after the system is vacuumed.

The above is the relevant treatment of organic waste gas treatment refrigerant leakage. If the Wuxi LNEYA organic waste gas treatment equipment fails, it is recommended to solve it in time!

Recomendações relacionadas

-

Cooperação mundial contra a COVID-19, a LNEYA presta apoio dentro das suas possibilidades

2225Na fase atual de transmissão do vírus, é imperativo estudar medicamentos e vacinas eficazes contra o coronavírus. Como fabricante de tecnologia de controlo de temperatura de alta precisão, acreditamos que é da nossa responsabilidade apoiar o trabalho...

Ver detalhes -

LNEYA Câmara de teste de alta e baixa temperatura de líquidos Câmara de teste

1700High and low temperature impact chamber is a necessary test equipment of material such as metal, plastic, rubber, electronics and so on, used for testing material structure or composite material. It can figure out the tolerance degree in the inst...

Ver detalhes -

Instruções de deteção de falhas do compressor do termóstato de aquecimento e arrefecimento com semicondutores

1320In the semiconductor heating and cooling thermostat, the compressor is one of its core components. Once it fails, it will affect the operation of the whole system. How to solve the fault is better? The faults of semiconductor heating and cooling t...

Ver detalhes -

É correto prolongar a duração da bateria baixando a temperatura ambiente?

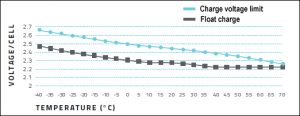

1539The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Ver detalhes

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor