Todos os modelos de refrigeradores de arrefecimento direto

KDS -75℃~200℃

sonda térmica

Cooling capacity -40℃@600W

Temperature Accuracy ±0.2℃

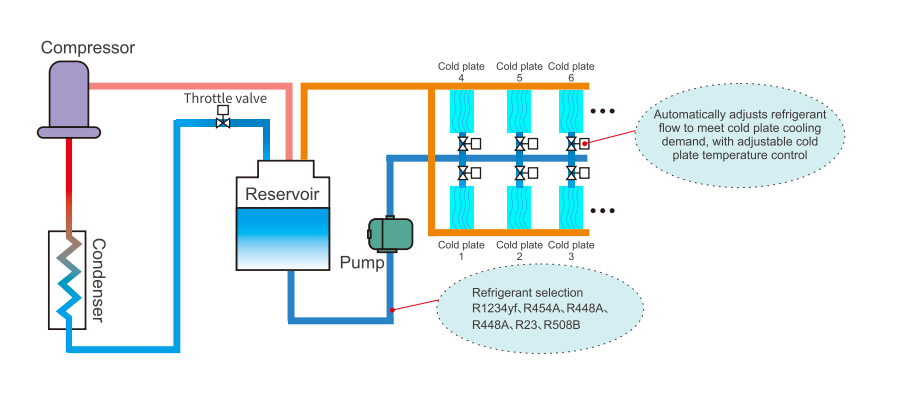

ZLJ & SLJ -150℃~-110℃

refrigeradores de temperatura ultra baixa

Capacidade de arrefecimento 0,4kW~11kW

temperature accuracy ±1℃

MD -75℃~225℃

mandril térmico

Heating & Cooling -60°C to +25°C: 2 min &+25°C to -60°C: 6 min

temperature accuracy ±0.5℃

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor