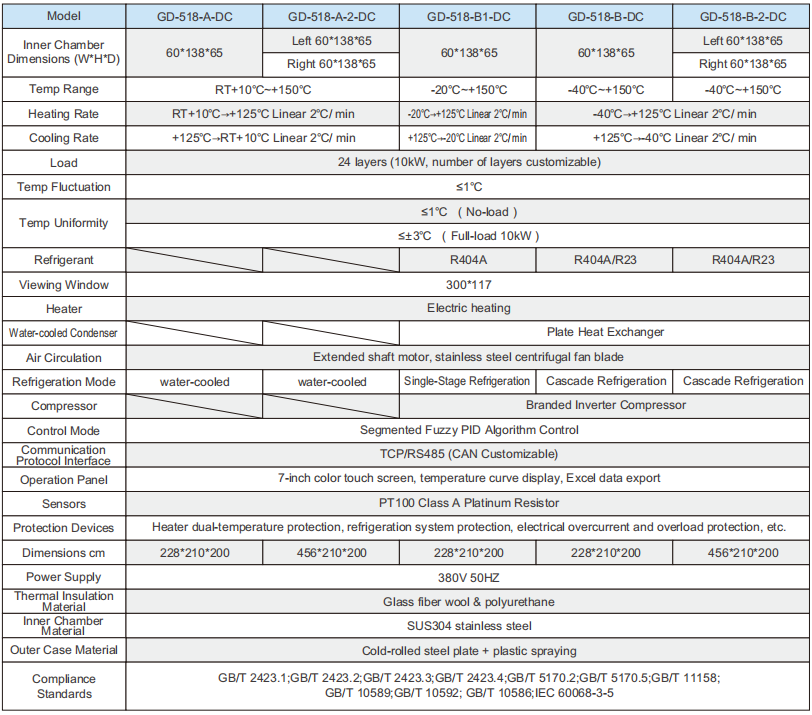

Todos os modelos de câmaras de teste ambientais

GD -40℃~100℃

câmara de ensaio de baterias

Capacidade de arrefecimento 1.8kW~15kW

Potência de aquecimento 6 kW~15 kW

Temperature uniformity ±1℃

GD -80℃~150℃

câmara de ensaio climático

Heating rate (+20~+150℃)A:5℃/min

Cooling rate Carrying idler (+20~-40℃)5℃/min

GD -40℃~180℃

câmara de choque térmico

Low temperature -40~0℃

High temperature +60~+150℃

Temperature fluctuation ≤1℃

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor