Escopo de aplicação do resfriador de precisão LNEYA

The main application industries of LNEYA precision chiller include plastic industry, electronic industry, electroplating industry, medicine industry, food industry, vacuum coating industry and so on. These industries are the main application industries of precision chillers.

In the plastic industry: LNEYA precision chiller can accurately control the mold temperature of various plastic processing machines, reduce the plastic cycle, provide stable production and quality of the product.

In electronic industry: LNEYA precision chiller can stabilize the molecular structure of electronic components on the production line, increase the qualified rate of electronic components. LNEYA precision chiller is widely used in ultrasonic cleaning industry to prevent the volatilization of expensive cleaning agents and the injury to human body.

In electroplating industry: LNEYA precision chiller can effectively control the temperature of electroplating, enhance the density and smoothness of the plating, shorten the electroplating period effectively, highly improve the production efficiency and improve the quality of the product.

In vacuum coating, the LNEYA precision chiller can control the temperature of the vacuum coating machine conveniently and generate high-quality plating products.

In the medical industry, the LNEYA precision chiller effectively controls the temperature of fermented drugs. To make full use of the advantages of good cold water machines, the pharmaceutical enterprises should be able to continue the technological innovation. At the same time, the chiller manufacturers are constantly improving the cost performance and serving the pharmaceutical industry better.

In the machinery industry, the LNEYA precision chiller can quickly control the pressure of oil temperature, and at the same time can stabilize the oil temperature and oil pressure, thus prolong the working time of the oil, improve the efficiency of the mechanical lubrication, and greatly reduce the wear.

Recomendações relacionadas

-

Sistema de aquecimento e arrefecimento para caldeira de reação química processo de reação

1152No processo de reação química, a temperatura do material é um parâmetro importante do processo de produção. Por exemplo, na cristalização de sal, na separação de soluções, no pigmento orgânico e no processamento intermédio, o controlo da temperatura é particularmente importante...

Ver pormenores -

How to choose the model of the temperature control device of the lithography machine?

884How to choose a suitable industrial chiller, and what aspects should be paid attention to in the design of the unit?1. Choose air-cooled or water-cooled temperature control device for lithography machineThe condensation methods of industrial chil...

Ver pormenores -

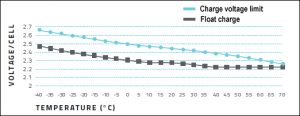

Is it right to extend battery life by lowering the ambient temperature?

955The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Ver pormenores -

How to choose a glass reactor? How to match the temperature control system?

947Glass kettle reactors are required for many laboratory equipment and are generally used with temperature control systems. In the chemical and pharmaceutical fields, the imported glass reactor is basically a necessity, and the refrigeration heatin...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor