Product features of explosion-proof high and low temperature machine

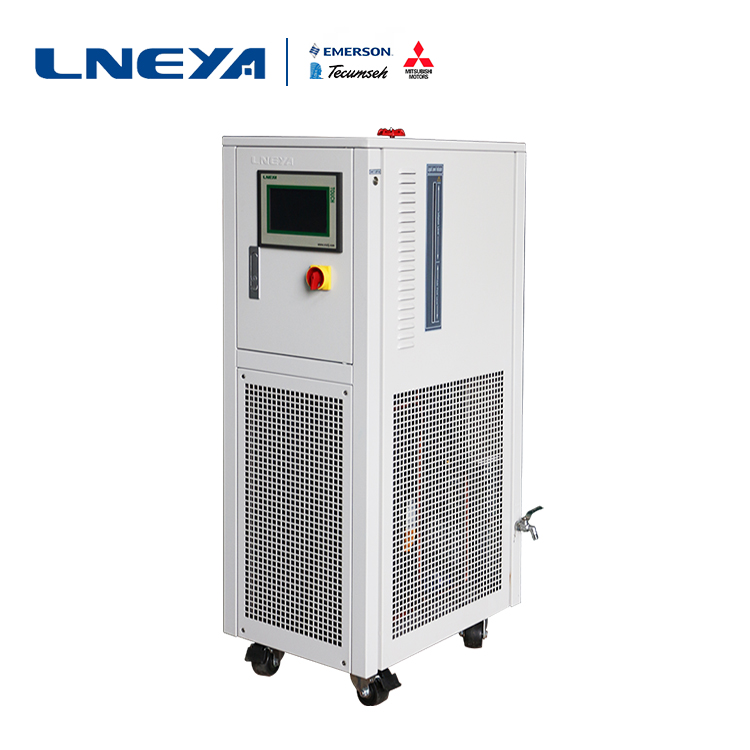

LNEYA explosion-proof high and low temperature machine is a relatively temperature control equipment that can be used in the current heating and cooling system. It can be used for simultaneous cooling and heating. It can be combined with various reactors for stable performance and reliable quality.

Explosion-proof high and low temperature integrated machine special relays, protectors, capacitors, refrigeration components, for the brand original high-quality devices, digital display temperature display, microcomputer temperature control, simple operation, eye-catching. The circulatory system is made of anti-corrosion material and has the functions of anti-rust, anti-corrosion and anti-cold liquid pollution. Explosion-proof high and low temperature integrated machine has energy saving. It can prevent circulating water scaling and anti-pollution when it is lack of water source, water quality and water pressure. It can effectively protect the normal operation of equipment under the bad working environment conditions in high temperature areas.

The explosion-proof high and low temperature integrated machine can meet the dynamic constant temperature control of the cold heat source of the high pressure reactor, the dynamic constant temperature control of the cold and hot source of the double glass reactor, the dynamic constant temperature control of the cold heat source of the double reactor, and the constant temperature control of the cold and heat source of the microchannel reactor. Small thermostat control system, temperature control of steaming system, low temperature and high temperature aging test of materials, combined chemical source cold source heat source constant temperature control, semiconductor equipment cooling and heating, vacuum chamber refrigeration heating constant temperature control and other temperature control needs. The equipment is especially suitable for the chemical, biological, physical laboratory, chemical industry metallurgical industry, colleges and universities, scientific research, genetic engineering, polymer engineering and other laboratories that need to maintain low temperature and work under normal temperature conditions.

No heat transfer medium evaporates at high temperature, and can achieve -80~190 degrees, -70~220 degrees, -88~170 degrees, -55~250 degrees, -30~300 degrees continuous control without pressure temperature. Ultra-high temperature cooling technology can directly cool down from 300 degrees high temperature. This principle and function have many advantages for the user: because only the heat transfer medium in the expansion chamber is in contact with the oxygen in the air (and the temperature of the expansion tank) At room temperature to 60 degrees, the risk of the heat transfer medium being oxidized and absorbing moisture in the air can be reduced.

LNEYA’s temperature control equipment adopts a fully enclosed pipeline design and uses a high-efficiency plate heat exchanger to reduce the demand for thermal fluid while improving the heat utilization rate of the system and achieving rapid rise and fall temperatures.

Recomendações relacionadas

-

Glycol chiller installation requirements

1121In the summer, the use of glycol chillers is relatively frequent. Efficient glycol chillers are also needed. Therefore, when installing glycol chillers, they need to be installed on a smooth and tidy floor. Why choose a smooth ground when installi...

Ver pormenores -

Sistema de controlo da temperatura da caldeira de reação

784The reaction kettle temperature control system is an automated equipment used to precisely control the temperature of materials inside the reaction kettle, widely used in fields such as chemical, pharmaceutical, biochemical, and material sci...

Ver pormenores -

Sistema de arrefecimento do grupo motopropulsor da transmissão com evaporador

961O evaporador é um dos quatro principais componentes do sistema de refrigeração e é a personificação definitiva do efeito e da eficiência da refrigeração. O evaporador é geralmente concebido e equipado pelo sistema de arrefecimento do grupo motopropulsor ...

Ver pormenores -

Recomendações para a utilização de equipamentos de ensaio de pastilhas integradas no processo de ensaio

1027Do ponto de vista de toda a indústria de semicondutores, os semicondutores podem ser divididos em fases de I&D, produção e aplicação. Nas diferentes fases, o papel dos ensaios é diferente. O controlo do equipamento de ensaio, incluindo máquinas de ensaio,...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor