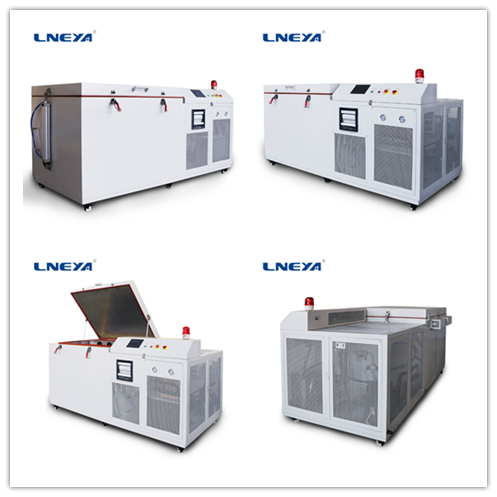

Instruções de utilização do frigorífico criogénico industrial

Os frigoríficos industriais são uma das máquinas de água fria. São classificados de acordo com o modo de arrefecimento da própria máquina de água fria. Dividem-se em frigoríficos de refrigeração a ar e frigoríficos de refrigeração a água. Caraterísticas estruturais: a ...

Structural features: a standard refrigerator freezer is composed of a compressor, condenser, evaporator, filter drier, expansion throttling valve of the five most series, note the amount of refrigerant inside (refrigerant), the electrical appliances (including controller) according to the requirement of the environment and control the operation of the compressor to achieve the purpose of heat transfer and refrigeration.

With the progress of the society, the industry has also been developed rapidly. Today, we will discuss the use of the laboratory refrigerator (industrial refrigerator).

1. Always check the sealing strip of the outer door.

2. Place it firmly and horizontally on the ground when carrying.

3. Clean the filter once a month (use a vacuum cleaner to suck, rinse it with water, finally dry and reset the filter), and suck the dust on the internal condenser with a vacuum cleaner in every two months.

4. When defrosting, you should cut off the power and open the door. When the ice and cream begin to melt, put in each layer of the refrigerator clean and bibulous cloth.

5. Clean it every month to make sure it is clean.

6. Remove the small amount of the dustin the fridge on the internal and external and accessories with dry cloth. If the fridge is too dirty, use neutral detergent and wash thoroughly with clean water after washing. Do not rinse the inside and upside of the refrigerator with water, otherwise, it will damage the insulation and cause failure.

7. Don’t put the lubricating oil to the compressor and other mechanical parts.

8. Take care when cleaning the fans in the back of the compressor.

9. The maintenance and maintenance of cryogenic refrigerator is particularly important to extend the life and the normal use. If the temperature control is not accurate, it often leads to damage the saved objects which will cause great influence to the experimental results, thus affecting the normal work.

Recomendações relacionadas

-

Qual é o refrigerante do refrigerador de recirculação

1040Different industries have differentrequirements for the refrigeration temperature of the recirculation chiller, sothe selected refrigerant is also different. When choosing a recirculationchiller, it is also necessary to have a clear understandi...

Ver pormenores -

Precauções para a inspeção de fugas do refrigerador de glicol

1563The main points about checking leakage of glycol chillerDuring the operation of the glycol chiller, it is critical that the refrigeration system does not leak. In order to avoid the leakage of refrigerant and other gases from the glycol chiller, ...

Ver pormenores -

Analysis of operating parameters and working conditions of automobile power module cooling system

1150Before choosing, you need to know what factors are related to the operating parameters and working conditions of the automotive power module cooling system. Then, from which aspects? 1. Evaporating pressure and evaporating temperature In the ope...

Ver pormenores -

Powertrain test cooling system-chiller maintenance

1134The powertrain test cooling system-chiller is one of the cooling systems. It has the characteristics of higher application efficiency and lower total energy consumption, and has generally been favored by many companies. However, no matter what kin...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor