Explicação da refrigeração para o compressor de parafuso do circulador do refrigerador de baixa temperatura

Because of the different compressors, the performance of the refrigerador de baixa temperatura circulators is also different. Screw compressors are different from piston compressors, and the structure is more precise. Therefore, if users need to choose the refrigerador de baixa temperatura circulators, they need to have their own understanding of their refrigeration operation.

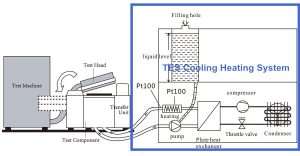

The screw compressor of the refrigerador de baixa temperatura circulator sprays lubricating oil into the working chamber when it works, which plays the roles of lubrication, cooling, sealing and silencing, as well as lubricating oil of main bearing, thrust bearing and shaft seal, pushing oil piston and balancing piston, after which the compressor is discharged by mixing with high-pressure gas.

Inhalation filter:

Inhalation filter of the refrigerador de baixa temperatura circulator is mainly composed of shell and metal filter. Install the suction thermometer, pressure gauge and oil valve on the shell. The oil valve is the refueling part of the unit when it is running, so more attention should be paid to it.

Oil cooler: Lubricating oil separated from circulating oil of the refrigerador de baixa temperatura circulator increases temperature (near exhaust temperature) because it absorbs frictional heat and heat of gas. High oil temperature and low viscosity will weaken sealing effect, increase internal leakage and reduce the efficiency of compressor. Therefore, lubricating oil must be cooled before it can be recycled. The circulating oil cooler of cryogenic water chiller plays the role of cooling oil.

Crude oil filter: In order to protect the normal operation of the circulating oil pump of refrigerador de baixa temperatura, the impurities are filtered through the crude oil filter before the lubricant enters the oil pump. For the first running machine, the cleanliness of the crude oil filter should be checked after the first running, and the filter screen should be disassembled regularly according to the cleanliness of the system. The filter can be cleaned with gasoline or kerosene and blown clean with dry air before continuing to use.

Recomendações relacionadas

-

O significado da temperatura nos ensaios de IC

1475Cada circuito integrado (CI) passa por dois tipos de testes antes de poder ser vendido e utilizado para construir um produto: o primeiro é chamado de teste de bolacha; o segundo é chamado de teste final. Com a melhoria da tecnologia de teste elétrico de circuitos integrados...

Ver pormenores -

Instruções para o ensaio de componentes das empresas de inspeção de pastilhas

979Com o desenvolvimento contínuo da indústria de testes de componentes, surgiram empresas de testes de chips, e a LNEYA também introduziu equipamentos de teste de componentes para testes de chips. O vetor de teste da empresa de inspeção de chips é armazenado no v...

Ver pormenores -

Instruções para o congelador 100p de LNEYA

1174Quando o utilizador comprar e utilizar o congelador 100p, a LNEYA terá instruções de utilização relevantes que serão enviadas ao utilizador juntamente com o aparelho. Então, a que é que devo prestar atenção quando utilizar o congelador 100p? Ao receber o equipamento, o utilizador deve...

Ver pormenores -

Precautions for purchasing reactor temperature control system

1141The reactor temperature control system is applied in the reaction tank for cooling, heating, and temperature control. It has the function of providing low and high temperatures, and can meet the different needs of different customers. Therefore, ...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor