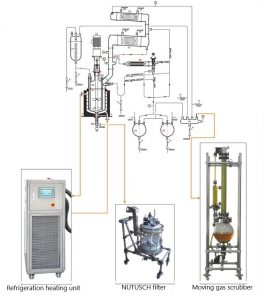

SUNDI Cooling And Heating System-R & D testing of organic synthetic materials and fine chemicals

LNEYA’s customer is a research institute engaged in the research, development and production of high-performance, environmentally-friendly new organic materials and fine chemicals.

The adhesives produced by customers can be used in integrated circuits, quartz crystals, printed circuit boards, etc .; engineering plastics are used in aerospace, electronics and electrical, precision machinery, office automation equipment, instruments and meters. One of the characteristics of the product is high temperature resistance and ultra low temperature. In this way, it can better meet the bonding of semiconductor packaging, quartz crystal component potentiometer lead-out electrodes, and other electronic components. long-term use.

(The picture comes from the Internet. If you have any questions, please contact LNEYA customer service)

Then during the R & D and production process, the product’s high temperature resistance and ultra low temperature performance need to be tested before it can be put into production. LNEYA’s cooling and heating system SUNDI series has a control temperature range of -120 ℃ to 350 ℃, superior performance and high precision, continuous control can be achieved in the range of -80 ℃ to 190 ℃, ultra-low temperature cooling technology can be directly Let it cool down.

The SUNDI series uses high-efficiency plate heat exchangers to reduce the need for hot fluid utilization, while enabling the system to achieve rapid temperature rise and fall. The whole system is a closed liquid circulation system, with the expansion of the container, the thermal insulation of the expansion container and the liquid circulation are adiabatic, it does not participate in the liquid circulation, only through mechanical connections. High cooling power from 0.5 to 1200kW, the highest production stability and repeatable temperature control, extending the thermal conductivity of the liquid, no need to change the liquid medium during the cooling and heating operation, single-fluid medium temperature control, saving production costs

Recomendações relacionadas

-

How to choose a hydrogen chiller?

844The chiller (also called cooling system or chiller) in the hydrogen production process is one of the key components to ensure the stable operation of the hydrogen production equipment. The chiller helps maintain the electrolyzer, reactor a...

Ver pormenores -

Introduction to mixed solution of glycol chilling systems (glycol chillers)

881Glycol chillers are industrial refrigeration systems that use a type of antifreeze called glycol, mixed with water, to lower the freezing point in the application of the chilling system. Glycol is a class of organic compounds that belong to the ...

Ver pormenores -

Como tornar os chillers de recirculação de temperatura ultra baixa mais económicos em termos energéticos

1052Nos tempos modernos, a proteção ambiental e a poupança de energia são o tema do desenvolvimento, assim como o chiller industrial. Então, como melhorar o seu chiller industrial para ser mais conservação de energia? Em primeiro lugar, para prevenir e reduzir a incrustação de tubos de...

Ver pormenores -

Como resolver o problema da falha da bomba de circulação da bomba de refrigeração?

1068Os dispositivos de aquecimento por refrigeração são necessários em muitas aplicações químicas, farmacêuticas e laboratoriais. Então, como resolver a falha do dispositivo de aquecimento de refrigeração também está preocupado com a forma de resolvê-lo? 1. Falha da bomba de circulação A bomba de circulação...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor