condições de ensaio de carregamento da bateria a diferentes temperaturas ambiente

At present, the battery is undoubtedly the most core and critical component in electric vehicles. Therefore, both the OEM and the battery factory need to conduct a comprehensive test of the battery. The characteristics of automotive lithium-ion power batteries are greatly affected by ambient temperature. In low temperature environment, the available energy and power attenuation is more serious, because long-term charging in low temperature environment, the life will be greatly shortened.

In the case of -10 degrees, the battery capacity and operating voltage are significantly reduced; in the case of -20 degrees, the discharge capacity decreases sharply, and the specific capacity is only about 30% of that at normal temperature. Charging at low temperatures is also difficult. Metal lithium formed on the surface of the negative electrode is easy to accumulate. Further chemical reactions will cause internal short circuits in the battery, greatly reducing safety. In the measured temperature range, the internal resistance of the battery is higher under low temperature conditions, and the internal resistance becomes lower and lower as the temperature increases. The change of discharge energy is basically opposite to the change of internal resistance.

According to authoritative tests, the battery charging start current in hot cars is higher than cold cars, and the charging current is higher than cold cars, because the charging voltage is significantly higher than cold cars.

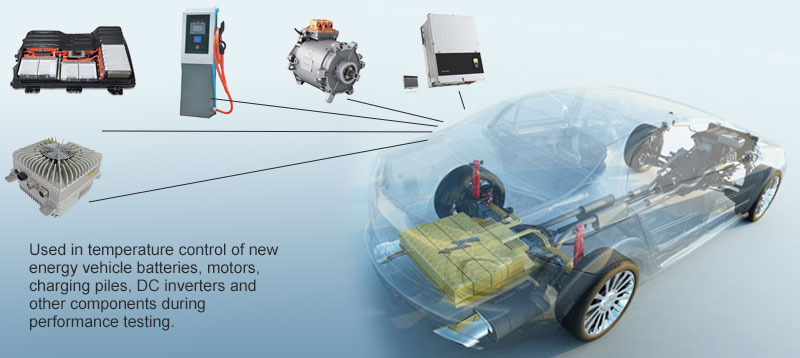

In these tests, the accuracy and temperature simulation become a very important factor. LNEYA’s KRY series-battery motor test cooling heating system is a product born for this emerging field. Fully enclosed tube design, high-efficiency plate heat exchanger, used for lifting temperature and constant temperature control in the test of new energy batteries and motors, especially suitable for heat dissipation and heat release process control during the test. With automatic fault protection function, it can output corresponding signals to ensure equipment safety. The main parts are international brands, quality assurance, the surface is treated with high-voltage electrostatic spraying, and auxiliary equipment can be added according to specific needs. It can achieve multi-channel temperature and flow control, one device can achieve multi-channel output, and each channel can control different flows without interfering with each other. Accepting customization requires solutions that control different flows and temperatures simultaneously.

Recomendações relacionadas

-

Descrição da classificação da seleção do refrigerador de baixa temperatura LNEYA

1268Different enterprises and different industries have different requirements for the low-temperature chiller of Wuxi Guanya (LNEYA). The choice of models is also different, so it is better to understand them in the selection. The low temperature chi...

Ver pormenores -

Invitation Letter | 10.17-19 Nanjing International Expo Center [5G18]

1306Our company will participate in the 81st APIChina China International Pharmaceutical Raw Material Intermediate Packaging Equipment Exhibition held at Nanjing International Expo Center from October 17-19, 2018. At that time, we will exhibit refrige...

Ver pormenores -

What are the main hazards of the reaction kettle in the reactor intelligent temperature control syst

1125The intelligent temperature control system of the reactor is used in various chemical fines. With the constant attention of the industry safety issues, some risk factors of the intelligent temperature control system of the reactor should be avoide...

Ver pormenores -

Vantagens dos termóstatos de processo do reator

931O termóstato de processo da caldeira de reação pode controlar a temperatura do meio e a temperatura do material. É adequado para utilizadores que requerem uma tecnologia de reação e um controlo de processo mais precisos. É utilizado principalmente em...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor