Is the temperature control equipment for semiconductor component testing a chiller?

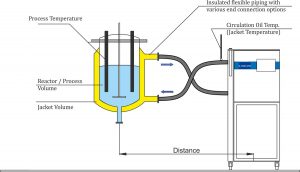

Semiconductor component testing temperature control equipment is used in the simulation test of the temperature performance of semiconductors, chips and other components, and conducts temperature tests in different temperature ranges within the range of -85~200℃.

One, equipment background

In the component industry, the requirements for various semiconductors and chips are relatively high. It is particularly necessary to test the performance status of components in different environments, as well as different temperature tests and other performance tests under packaging and assembly production, so as to avoid components such as components. After entering production, the electronic products are actually put on the market and face a variety of unusual environments that cause the electronic components to be unusable.

Second, role

Semiconductor component testing temperature control equipment performs high and low temperature cycle testing, high and low temperature temperature impact testing, failure analysis and other reliability tests on components, integrated circuits, modules, PCBs, assembly and other applications. In addition to semiconductor component testing temperature control equipment, industry professionals can also call them heat flow meters, hot and cold air impact machines, temperature forced systems, high and low temperature air circulation systems, and semiconductor testing chiller.

Recomendações relacionadas

-

Máquina de arrefecimento de água quente e fria a alta e baixa temperatura para teste de motor de bateria

1043O refrigerador de água integrado de alta e baixa temperatura e calor LNEYA é utilizado na gestão térmica da bateria de veículos eléctricos de energia nova. O princípio relevante aplicado na gestão térmica é o seguinte: o refrigerador de água integrado de alta e baixa temperatura...

Ver pormenores -

Quais são os factores que influenciam o frigorífico industrial com menos 200 graus?

1002Para utilizar melhor o frigorífico industrial com uma temperatura de menos 200 graus, é necessário compreender alguns factores de influência e como evitá-los. A temperatura do óleo terá um efeito importante na viscosidade do frigorífico industrial...

Ver pormenores -

Análise de falhas comuns no sistema de teste de baterias de veículos de energia nova

947Se a bateria do veículo de energia nova vazar, o modo de manifestação de falha geral: a luz OK do medidor não acende, o medidor solicita a verificação do sistema de energia, a falha de vazamento do sistema de alta tensão, desconecte a bateria e o b...

Ver pormenores -

The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

991Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor