How to choose the chiller for cooling the mixing tank?

Mixing tanks are used in coatings, medicine, building materials, chemicals, pigments, resins, food, scientific research and other industries to stir, mix, blend, and homogenize materials. The mixing tank will generate heat during the mixing process, what cooling is used for the mixing tank? The chiller is a device that can maintain constant temperature, constant temperature and constant flow. Cooling the medium with a stirred tank can help.

1. When the mixing tank needs a temperature range of 5 degrees to 30 degrees, use a high-temperature chiller to cool down the mixing tank. When adding ethylene glycol solution to the high-temperature chiller, the temperature can be -5 degrees.

2. When the mixing tank needs to be controlled within the temperature range of -5 degrees to -35 degrees, a medium temperature chiller is used to cool down the mixing tank. The medium-temperature chiller can use ethylene glycol or brine as the refrigerant. When using brine as the refrigerant, the evaporator needs to be anti-corrosion designed.

3. When the mixing tank needs to be controlled in the temperature range of -40 degrees to -120 degrees, a low-temperature chiller is used to cool down the mixing tank.

Depending on the material requirements of the mixing tank, some of them need to be heated. At this time, a cold and hot water chiller can be used. This is a temperature control device that can both cool down and raise the temperature. The temperature control range is from -120 degrees to 200 degrees.

If the mixing tank is used in an environment containing explosive gas, use an explosion-proof chiller to cool down the mixing tank.

Some of the materials in the mixing tank need to be heated, dried or cooled. The cooling cycle uses water to circulate inside and outside the jacket so that the materials will not form agglomerates or stickiness at a certain temperature. It can also be heated or cooled by adding coils and other forms according to user requirements.

If there are technical requirements for the cooling of the mixing tank, it can be customized according to the actual requirements. Please contact us. LNEYA is a manufacturer with exclusive technology and independent research and development and production of industrial temperature control equipment such as chillers.

Recomendações relacionadas

-

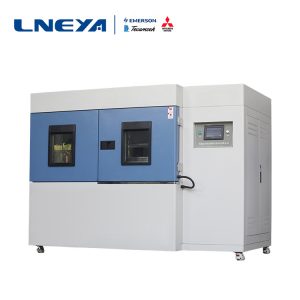

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1173The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

Ver pormenores -

What Decides the Price of the Heating Cooing Circulator?

928The price of heating cooling circulator is determined by raw materials, manufacturing overhead, technical cost, impacting on the final quotation. The heating cooling circulator is made of shell and internal parts. The shell is applied standard SUS...

Ver pormenores -

Quais são os efeitos de uma falha de energia na caixa frigorífica criogénica de azoto líquido?

1194Different industries have different temperature requirements for liquid nitrogen cryogenic cryostats. Of course, there are many types of cryogenic cryostats. The refrigeration methods used in different industries are different. Wuxi Guanya LNEYA u...

Ver pormenores -

Colocação em funcionamento de equipamento de refrigeração de água circulante para empresas químicas

1009Depois de concluída a instalação de refrigeradores de água circulantes em empresas químicas, é necessário efetuar algumas depurações nos refrigeradores de água circulantes para produtos químicos industriais na fase inicial de funcionamento. Só através de uma depuração cuidadosa...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor