What is the temperature control method of the reactor?

The reaction kettle used for temperature control has a large capacity and a thick wall, so it is a controlled object with a large heat capacity and a long pure lag time. As the reaction progresses, the heat transfer coefficient of each heat transfer medium changes nonlinearly, and the The changes of various external environments are relatively sensitive; in addition, the gain of the reaction process will change greatly, and even the direction of gain change is different; and as the reaction progresses, the solid particles in the kettle will increase, and the heat transfer coefficient of the kettle will also increase. With irregular changes.

Due to the complexity and nonlinearity of the exothermic process of the chemical reaction during the reaction process of the reaction kettle temperature control method, the heat transfer coefficient of each heat transfer medium changes nonlinearly, and is sensitive to the influence of various external disturbances, so that the control has a certain degree of control. difficulty. If the heat is not removed in time and unevenly during the reaction process, the reaction temperature will continue to rise, and it is easy to cause “flying temperature” phenomenon due to local overheating, resulting in “burst”; on the contrary, if the heat is removed too much, it will cause The reaction temperature has been falling, causing the reaction to go out. The main factor for the quality of the polymerization reaction is the quality of the temperature control of the reactor. The change of temperature will directly affect the quality and output of the product, so the temperature control in this process is the key point and also the difficulty.

Reactor temperature control method The chemical reaction mechanism of the reaction process is relatively complicated, especially the design materials, energy balance, reaction kinetics, etc. of the polymerization reaction process, plus external conditions such as raw material purity, catalyst type, change in the amount of raw material added, hot water temperature , the change of circulating coolant flow rate, etc. have a great influence on the system, and it is difficult to derive the mechanism model; and because of the complexity and nonlinearity of the exothermic process of the chemical reaction.

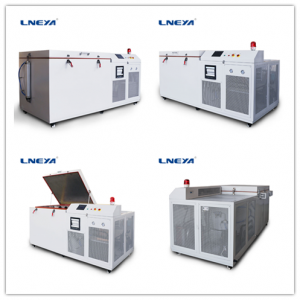

Reactor temperature control method and technology is a relatively complicated topic in the field of refrigeration and heating. LNEYA is also constantly advancing and making progress in the field of refrigeration and heating.

Recomendações relacionadas

-

Como escolher o resfriador de água tipo parafuso

1237Em comparação com os chillers semelhantes, o chiller refrigerado a água do tipo parafuso tem muitas vantagens. Nós, como um dos principais fabricantes de chillers, compartilhamos mais. 1. A temperatura do líquido condutor de calor pode ser ajustada para qualquer temperatura que você quiser,...

Ver pormenores -

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1063Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

Ver pormenores -

Description of the action of the filter in the ultra-low temperature compressor unit

1079In order to stabilize the operation of the ultra-low temperature compressor unit, the performance of the compressor is very important, and in addition to the compressor, the filter is also important. In order to maintain normal operation, it is ne...

Ver pormenores -

Como funcionam os refrigeradores de semicondutores CVD e PVD?

1025O princípio de funcionamento dos refrigeradores utilizados nos processos de deposição química de vapor (CVD) e de deposição física de vapor (PVD) de semicondutores consiste principalmente em remover o calor gerado durante o processo através da circulação de água de arrefecimento ou de...

Ver pormenores

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor