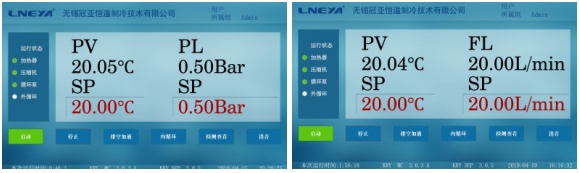

ALL environmental test chambers model

GD -40℃~100℃

câmara de ensaio de baterias

Capacidade de arrefecimento 1.8kW~15kW

Heating power 6KW~15KW

Temperature uniformity ±1℃

GD -80℃~150℃

câmara de ensaio climático

Taxa de aquecimento (+20~+150℃)A:5℃/min

Taxa de resfriamento Transportando a polia (+20~-40℃)5℃/min

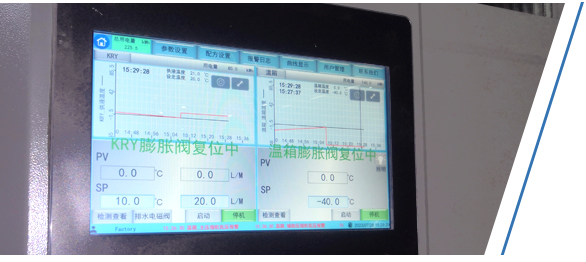

GD -40℃~180℃

câmara de choque térmico

Baixa temperatura -40~0℃

Alta temperatura +60~+150℃

Flutuação de temperatura ≤1℃

LNEYA Refrigeradores industriais Fabricante Fornecedor

LNEYA Refrigeradores industriais Fabricante Fornecedor